Chain and Chain Drives

New Focus: Stainless Inverted Tooth Chains

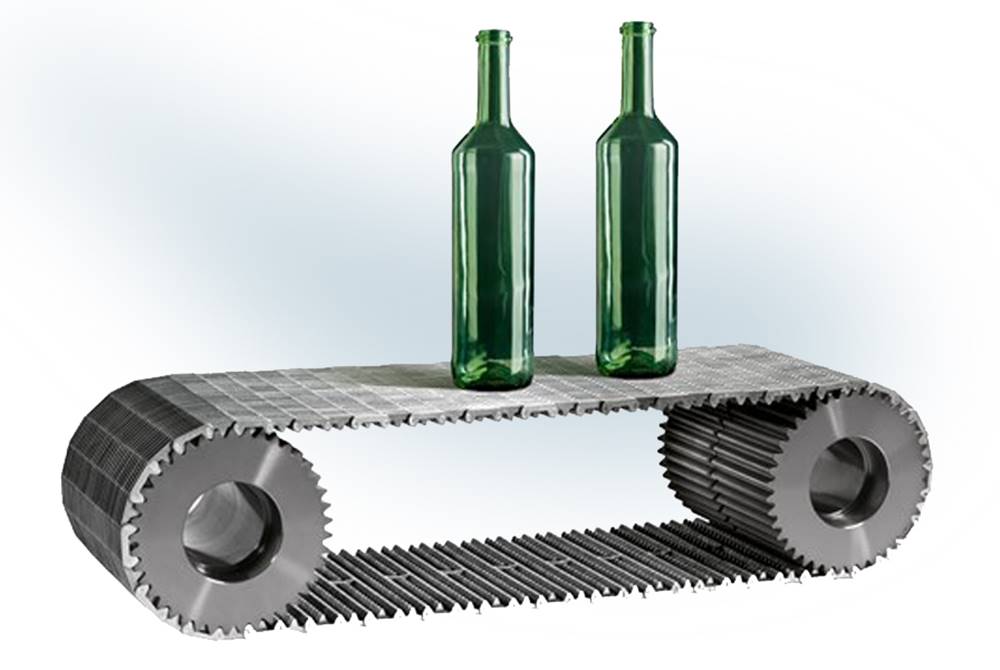

“Admittedly, the designation ‘stainless inverted tooth chains’ may be confusing – because the advantage of our stainless steel inverted tooth chains is not in the resistance of the metal but in the thermal conductivity properties of stainless steel” emphasizes Uwe Gillert, glass industry manager for inverted tooth chain manufacturer RENOLD.

Renold Tooth Chain introduced the stainless steel inverted tooth chain over 20 years ago and for more than 25 years Uwe Gillert has frequently visited and supported designers, maintenance staff and production managers in glass plants and at the factories of equipment manufacturers. During this time, he has accumulated wide and detailed knowledge regarding the industrial production of glass containers. He uses his experience and customer input to initiate product improvements and modifications to our Renold conveyor tooth chains. Recently, specific adjustments have been made to our original standard stainless steel chains to increase the range of use and lifetime, but of course, the beneficial features of our product design will still be incorporated into our chain.

As stainless steel has a lower thermal conductivity than standard steel, the interface temperature between the burning hot glass and the inverted tooth chain increases. “This way, base cracks in the glass are reduced, which results in minimal waste during production,” explains the inverted tooth chain specialist. Preheating the inverted tooth chains is also no longer necessary. For a standard IS-machine, this can save energy costs of tens of thousands of Euros per year.

Of course, the stainless steel variant also features the classic advantages of the inverted tooth chain design: Full flexible design using spacer rings, extended pitch or any other layout. The interlocking power transmission between the inverted tooth chain and the sprocket ensures slip-free drive operation. The inverted tooth chain engages with the sprocket with minimal impact to minimize energy loss. The 2-pin rolling pivot joint features virtually zero friction loss. This results in efficiencies of up to 99% and reduces wear significantly.

Another feature of our tooth chain, laser-welded rolling pivots offer major advantages in the glass industry. The smooth contact surface on both sides of the inverted tooth chain creates a gap-free transition between the inverted tooth chain and the in feeding and transition points. This process also reduces the risk of pin breakage. Hardened outer link plates ensure a wear-resistant and safe connection.

Further information regarding stainless steel inverted tooth chains and the cost savings attributed to them can be obtained from us on request.

-

Drive systems4 years ago

Drive systems4 years agoIntelligent frequency inverters for digital production

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoThe necessity of bolted flange connection training

-

Motors7 years ago

Motors7 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors7 years ago

Motors7 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives6 years ago

Gear drives6 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors7 years ago

Motors7 years agoGet a first-class ticket to productivity

-

Motion control6 years ago

Motion control6 years agoWhere the robots come from?

-

Motion control6 years ago

Motion control6 years agoRexnord to Acquire Centa Power Transmission

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoCustom hobbing tool enables 45-degree angles

-

POWER TRANSMISSION TECHNOLOGIES3 years ago

POWER TRANSMISSION TECHNOLOGIES3 years agoEUROTRANS Board meets for its first session in 2021