Gear drives

Klingelnberg at control 2018: Tactile and optical measurement on one machine

At the world’s leading trade show for quality assurance, Control in Stuttgart, some 900 manufacturers of QA equipment will present their innovations from April 24 to 27, 2018. This year at Booth 6310 in Hall 6, systems supplier Klingelnberg, a leading manufacturer of precision measuring centers for the gear industry, will cover a broad range of topics, including the innovative field of optical metrology, with a range of P-series models. Here, the company is entering brand new territory.

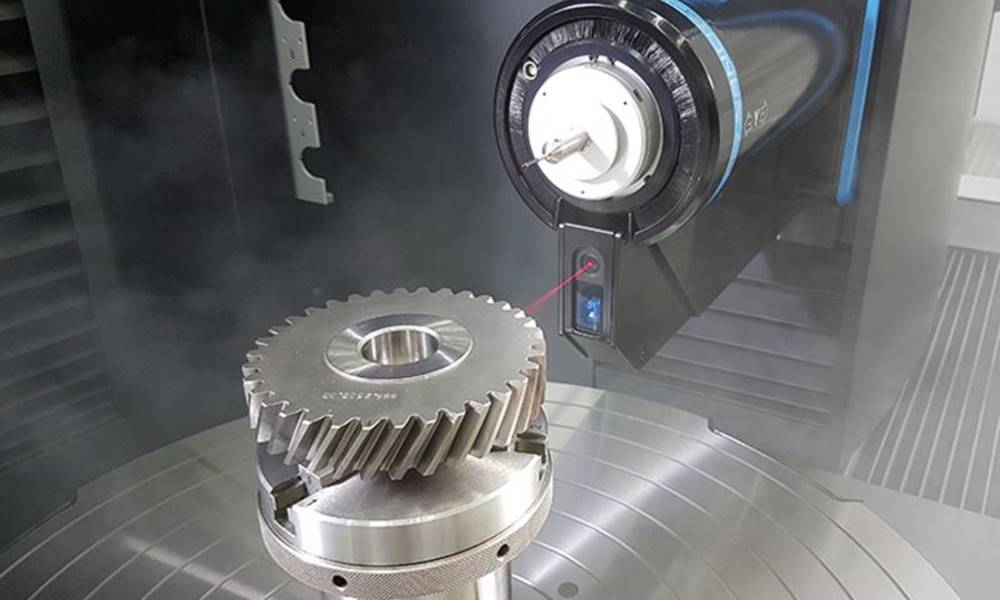

Klingelnberg Precision Measuring Centers are used throughout the world for accurate measurement of gears and high-precision, axially symmetrical components. These measuring machines ensure that reliable measurement results are obtained not just in measurement rooms and geometry laboratories, but also in the shop-floor environment. The P series stands out for its patented, high-precision 3D NANOSCAN probe system as well as an easy-to-use roughness probe system, among other features. These tactile sensors have now been upgraded with a powerful optical sensor.

New possibilities: High-speed measurement data logging and high point density with Klingelnberg Optical Metrology

Klingelnberg Optical Metrology is a smart combination of tactile and optical metrology – and that is precisely what makes it different from other systems. An extremely rapid changeover from the tactile system to the optical sensor makes this a hybrid system that combines the advantages of both measurement methods. The high-precision tactile measurement is ideally complemented by high-speed optical measurement data logging with a high point density.

Of course, a purely optical measurement is also possible. At Control, Klingelnberg will demonstrate high-speed, complete 3D digitizing of gear components, among other things. The measurement result takes the form of a high-resolution 3D point cloud, which can be evaluated in a number of ways or can undergo further processing as a CAD file.

“The development work for optical metrology is based on a number of factors,” explains Georg Mies, Head of Precision Measuring Center Development at Klingelnberg. “These include our many years of experience in a range of research projects, our close contact with sensor developers, and, last but not least, our good relationship with technical universities and institutes. Thanks to an ongoing dialog with our customers, combined with decades of experience in gear metrology, we are very familiar with the requirements of optical metrology.”

The new precision is black: Klingelnberg presents a new machine design

The new generation of the P series, which Klingelnberg will be presenting to an international audience of industry professionals in Stuttgart, includes the two P-series Precision Measuring Centers ─ the P 26 and the P 65. Not only has their proven technology been systematically advanced, their machine design has also been thoroughly revamped. The new design centers on a longlife color concept with a concentration of dark gray hues. This makes machines used directly on the shop floor less prone to showing dirt.

P 65 – precision measurement with new, optional equipment options

In its “measurement toolkit” at Control, Klingelnberg has the new P 65 for medium diameter ranges, which makes use of this innovative measurement technology for the first time. The Klingelnberg Optical Metrology concept was successfully unveiled at the EMO 2017 trade show in Hannover, Germany, where it received a very positive customer response.

The new P 65 has even more to offer: For over a decade, Klingelnberg Precision Measuring Centers have been successfully operated on shop floors around the world using the optional three-point vibration isolation system developed by Klingelnberg. The integrated system familiar from the P 26 and P 40 has now also been implemented in the new P 65. Access to the C axis has also been significantly improved to achieve optimal workpiece loading. Thus, it was possible to increase the loading angle by over 50 % compared with the predecessor model of the P 65.

P 26 – roughness measurement for small diameter ranges

With the P 26, Klingelnberg now for the first time presents its tried-and-tested Precision Measuring Center for smaller diameter ranges in the new machine design. The machine and software concept of the P series is optimized for measurement of complex drive components.

The technology replaces up to four conventional measuring devices: gear measurement, general coordinate measurement, form measurement and roughness measurement. Every measurement task can be fully automated in a single setup. The Klingelnberg roughness measurement system, which has already been successfully used in several hundred P machines, also includes measurement of surface roughness on internal gears. What differentiates the Klingelnberg system from many others is the possibility of systematic measurement using a fully automatic CNC-controlled measuring procedure.

P 16 G – all-rounder for cost-effective process Monitoring

With the P 16 G, Klingelnberg has a measuring center for axially symmetrical components in its portfolio that is designed around measurement tasks outside of gears. Thus, instead of gear cutting software, the P 16 G is equipped with software for dimension, form, and position measurement as standard. Wherever gauges alone have previously been used for quality assurance, the P 16 G can perform the relevant measurements. The advantage: it measures any number of different components. A P 16 G can therefore replace component-specific gauges and multipoint measuring devices, which are capital-intensive and inflexible. In addition, this newest addition to the P series family, used directly on the shop floor, makes it possible to take advantage of statistical process control. This makes the P 16 G an economically appealing strategy for direct production monitoring.

Booth 6310, Hall 6: Experience expertise and industry know-how

Klingelnberg’s solutions bring it close to the market and the user – with regard to services and software solutions as well. Control visitors to Klingelnberg Booth 6310 in Hall 6 will be able to see this “live” for themselves. Professor Dr. Ing. Günther Gravel, Head of the Institute for Production Technology at the University for Applied Sciences (HAW) in Hamburg, will once again be available as an external expert for measurement analyses and for stimulating discussions of industry issues.

-

Drive systems5 years ago

Drive systems5 years agoIntelligent frequency inverters for digital production

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoThe necessity of bolted flange connection training

-

Motors8 years ago

Motors8 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors8 years ago

Motors8 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control7 years ago

Motion control7 years agoWhere the robots come from?

-

Motion control7 years ago

Motion control7 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES4 years ago

POWER TRANSMISSION TECHNOLOGIES4 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoCustom hobbing tool enables 45-degree angles

-

Motors8 years ago

Motors8 years agoInterroll introduces a new generation of drum motors