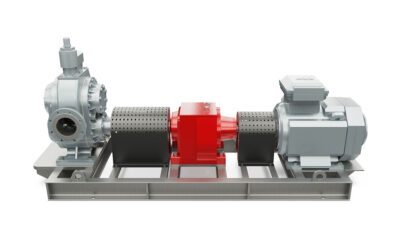

Reducer

Automation and mechanization in tea production

With a yearly consumption of 7.54kg of tea per person, Turkey is the first consumer (per capita/year) of tea around the world followed by Morocco(4.74kg/capita/year) and the United Kingdom ( 3.75kg/capita/year).

A big part of the local consumption is covered by the national production. Indeed, at the collapse of the Ottoman empire Mustafa Kemal Ataturk started a strategical plan to increase the production of tea. He aimed to reduce the importation of coffee and build a strong sector for future exportations. This switch in the consummation habits and production strategy succeeded as Turkey is now the 5th tea producer with more than 6% of the worldwide tea production.

Growing in the mounts of the black sea region, the tea trees are perfectly matching with the regular rains and high rate of humidity characteristic of the region. Covering most of the hills the leaves are harvested in the beginning of summer. There starts a season that will last 3 months. In this busy period, the production is non-stop and the machines are under heavy pressure and workload. We provide gearboxes and electrical motors to the complete production process. Our IRK, IR, IRS series are used to transport, steam, cut, sort, dry and pack the precious tea leaves. Depending on the leaves and type of tea produced, the transformation process is composed of 5 steps.

Steaming: The leaves are washed and treated with high pressured water steam. This step contributes to the fixation of the aroma and specific taste of the tea.

Oxidation: The leaves are “burnt” to activate the color and flavor proper to black tea. This step also reduces the natural acidity of the tea leaves.

Rolling : The steamed leaves are being cut in roller cutting presses, this operation give the final shape of the tea.

Drying : The tea is dried in screening ovens that separate the tea leaves in different categories and removes the small wood and structures.

Packaging : The freshly produced tea is packed and stocked in big paper bags, these are dispatched to distribution and packing centers around the country.

| This progress contributed to the development of natural teas growing without any usage of fertilizers of chemicals |

As a recent trend major producers and small cooperatives are using mechanization and automation systems to reduce the usage of fertilizer. Indeed, the producers used to grow tea leaves with chemical fertilizers to reach a faster maturity and standards size. Nowadays the mechanization of the production process is helping them to adapt the timing and parameters to each type of leaves. This progress contributed to the development of natural teas growing without any usage of fertilizers of chemicals. Showing how mechanization and automation can help producer to reduce their impact on the environment and considerably improve the quality of their products.

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoThe necessity of bolted flange connection training

-

Drive systems6 years ago

Drive systems6 years agoIntelligent frequency inverters for digital production

-

Motors9 years ago

Motors9 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors9 years ago

Motors9 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives8 years ago

Gear drives8 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control8 years ago

Motion control8 years agoWhere the robots come from?

-

Motion control8 years ago

Motion control8 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES5 years ago

POWER TRANSMISSION TECHNOLOGIES5 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoCustom hobbing tool enables 45-degree angles