Drive systems

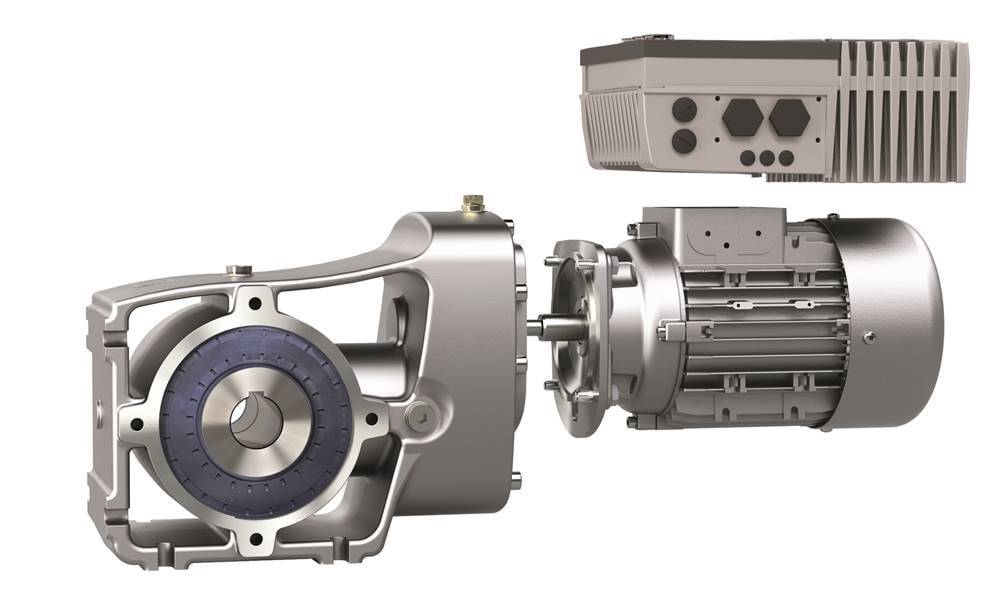

Intelligent frequency inverters for digital production

NORD DRIVESYSTEMS provides pioneering drive solutions for networking and connection of an Industry 4.0 environment. With pioneering hardware and software, NORD drive technology enables networked or autonomous production processes of the “Smart Factory” and keeps them running.

NORD drive systems fulfil all conditions for intelligent digitalised production with advanced maintenance concepts and new services. In combination with NORD frequency inverters , all NORD drives can be directly integrated as active components in Industry 4.0 environments throughout the world. The prerequisites for this are the internal PLC as decentralised intelligence and the extensive range of communication options of the NORD frequency inverters. Internal or global networking in the Industrial Internet of Things (IIoT) or connection to cloud solutions is possible at any time and opens up all the opportunities of Industry 4.0. Via their digital output interfaces, the drive units’ frequency inverters can control actuators in conveyor systems or production plants and therefore deliberately affect processes. Analogue and digital external sensor signals and data (e.g. from light barriers, temperature sensors or vibration sensors) can be received, processed and transmitted. Thanks to the integrated PLC that every NORD frequency inverter has on board, the decentralised drives can form master-slave groups that intelligently communicate with each other and take on control tasks autonomously. This supports the central control system and opens up numerous opportunities for a modular system design with production groups and production islands as well as for the intelligent networking of the entire factory up to the “Smart Factory”. Fast, efficient and comprehensive evaluation of analogue and digital data by the intelligent PLC in the drive electronics forms the basis for modern maintenance and servicing concepts such as condition monitoring and predictive maintenance.

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoThe necessity of bolted flange connection training

-

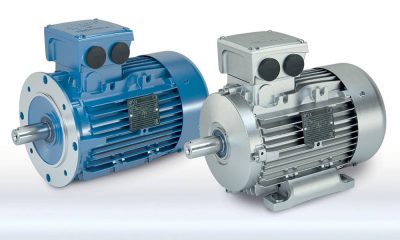

Motors9 years ago

Motors9 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors9 years ago

Motors9 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives8 years ago

Gear drives8 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control8 years ago

Motion control8 years agoWhere the robots come from?

-

Motion control8 years ago

Motion control8 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES5 years ago

POWER TRANSMISSION TECHNOLOGIES5 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoCustom hobbing tool enables 45-degree angles

-

Motors9 years ago

Motors9 years agoInterroll introduces a new generation of drum motors