Motors

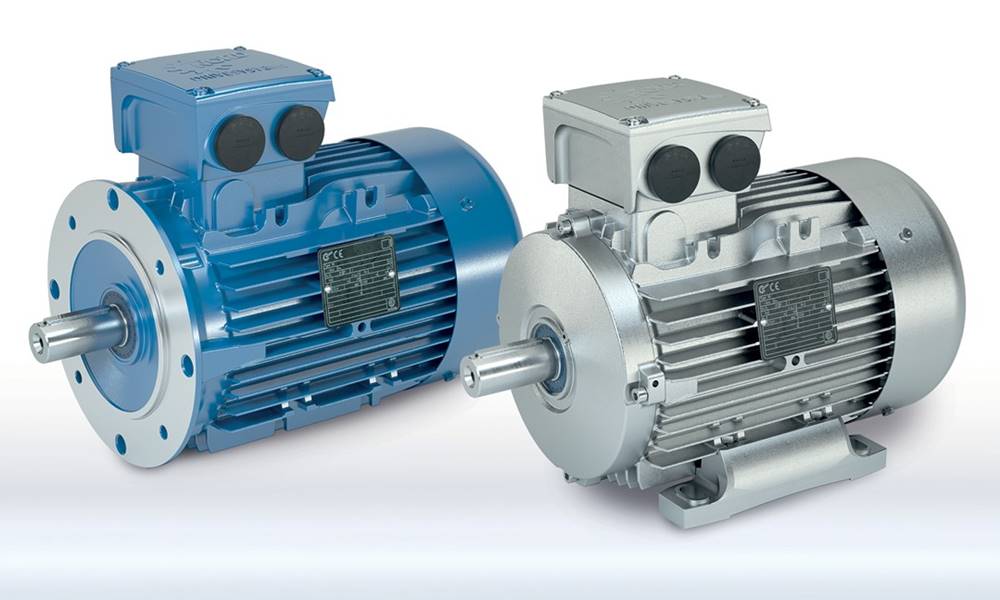

Optimised design for IE3 asynchronous motors

NORD has optimised the design of its proven IE3 asynchronous motors. The model maintenance applies to numerous details that further improve the electric motors´ function, assembly and operation.NORD has optimised the design of its proven IE3 asynchronous motors with numerous details that achieve a better assembly and cooling.

The facelift of the IE3 asynchronous motors from NORD DRIVESYSTEMS involves no change of electrical data and outer dimensions. They can be seamlessly used without adjustments in any existing application with NORD IE3 motors. The optimised cooling fin shape, an assembly-optimised fan and a new modern fan cowl enable a better heat dissipation and assembly. The fan cowl can be simply assembled in case a motor-mounted frequency inverter is used. The new cooling fins design enables an unhindered airflow around the terminal box. The revised terminal box is without sharp edges and corners and has reinforced feet for a better motor stability. Another important detail is the optimised incremental encoder mounting. Due to the fan cowl, the encoder is fully shock-resistant and not within the airflow, which further improves the cooling power. Retrofit mounting is also possible due to a plug-on shaft.

-

Drive systems4 years ago

Drive systems4 years agoIntelligent frequency inverters for digital production

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoThe necessity of bolted flange connection training

-

Motors7 years ago

Motors7 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors7 years ago

Motors7 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives6 years ago

Gear drives6 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors7 years ago

Motors7 years agoGet a first-class ticket to productivity

-

Motion control6 years ago

Motion control6 years agoWhere the robots come from?

-

Motion control6 years ago

Motion control6 years agoRexnord to Acquire Centa Power Transmission

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoCustom hobbing tool enables 45-degree angles

-

POWER TRANSMISSION TECHNOLOGIES3 years ago

POWER TRANSMISSION TECHNOLOGIES3 years agoEUROTRANS Board meets for its first session in 2021