Gearbox

ZF Presents EcoLife 2 Transmission System

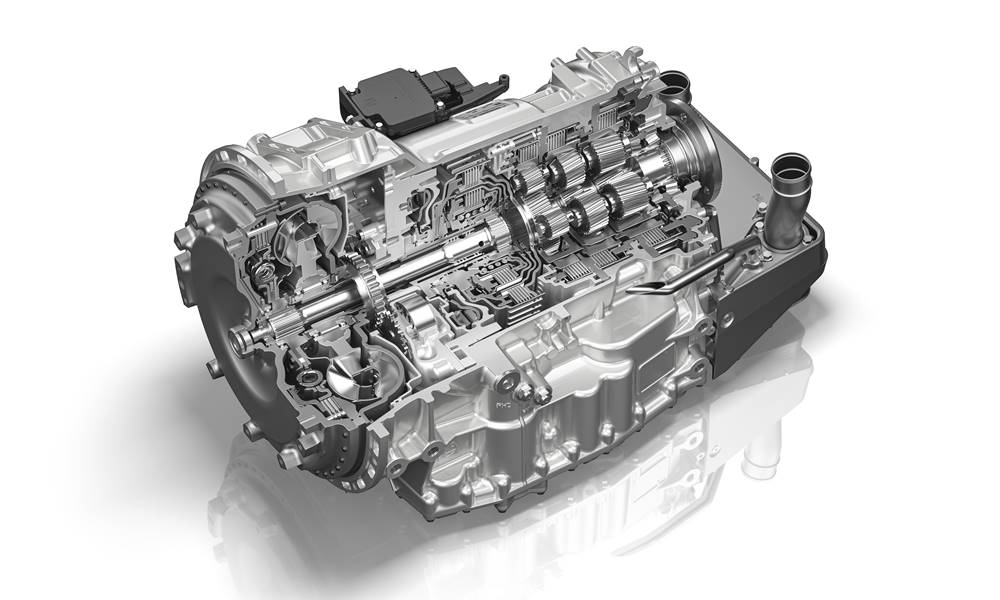

ZF presents the latest generation of its proven automatic transmission system for buses: numerous technical refinements make EcoLife 2 lighter, more efficient, more robust, and easier to maintain. The most significant improvements include possible fuel savings of up to three percent, stop-start capability for all model variants and reduced wear thanks to an optimized cooling concept. In the latest EcoLife generation, ZF has also further enhanced the comfort levels, with improved shift quality, as an example.

“ICE powered buses are still a central component of public transport systems and long-distance travel provision. It is therefore important to contribute to reduce emissions and increase efficiency in this area. The market demands high levels of comfort combined with best performance – we have achieved this with the new EcoLife 2,” says Dr. Andreas Grossl, responsible for bus axle and transmission systems at ZF.

ZF has retained the basic principle of a six-stage planetary gearset with torque converter and primary retarder in the second generation of the EcoLife transmission. Numerous technical modifications optimize the new version of the powershift transmission, allowing city and intercity buses to pull away gently with an input torque of up to 2,000 Nm which enables smooth gear shifting.

Economical, robust, and comfortable

A torque converter with a new torsional damper enables fast and smooth shifting. It also provides all model variants of the EcoLife 2 with a fuel-saving stop-start function. ZF has adapted the torque converter and torsional damper, satisfying the current trend toward low engine and transmission speeds which are important for efficient operation: the torque converter also transmits fewer engine vibrations to both transmission and complete drivetrain. This increases levels of comfort while minimizing wear.

There is also something new inside the gearbox: the planetary gearset of the EcoLife 2 makes it possible to increase the total gear ratio’s from 5,469 to 5,727, necessary for increased mechanical power transmission and thus for greater efficiency. ZF engineers were able to further reduce internal transmission losses by applying a special coating to the lamellar clutch. This coating also optimizes cooling, which in turn reduces wear.

Another innovation in the EcoLife 2 is the cooling concept. The stainless-steel heat exchanger mounted behind the transmission is now triple-ducted, integrating the transmission cooling system and eliminating the requirement for an additional container. The results is weight savings of around 10 kilograms and increased ease of maintenance.

Gearbox control creates further advantages

Further advantages of the EcoLife 2 result from the transmission control system. The control software is not only responsible for the extremely fast, smooth and more comfortable shifting: it equipps the new generation of city bus transmissions with a coasting function that contributes to fuel savings. Customers also benefit from the fact that the transmission software can also be adapted to a variety of different engine characteristics. ZF can provide the EcoLife 2 with different starting characteristics, according to customer requirements.

Further advantages include simpler assembly and easier diagnostics, for which ZF also offers preventive service packages through its international partner workshops.

EcoLife 2 will be made available to ZF’s existing customers by next year, after which it will be rolled out to the open market. An EcoLife 2 variant for coaches is also under development, covering the torque range between 1,700 to 2,800 Nm.

-

Drive systems4 years ago

Drive systems4 years agoIntelligent frequency inverters for digital production

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoThe necessity of bolted flange connection training

-

Motors7 years ago

Motors7 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors7 years ago

Motors7 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives6 years ago

Gear drives6 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors7 years ago

Motors7 years agoGet a first-class ticket to productivity

-

Motion control6 years ago

Motion control6 years agoWhere the robots come from?

-

Motion control6 years ago

Motion control6 years agoRexnord to Acquire Centa Power Transmission

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoCustom hobbing tool enables 45-degree angles

-

POWER TRANSMISSION TECHNOLOGIES3 years ago

POWER TRANSMISSION TECHNOLOGIES3 years agoEUROTRANS Board meets for its first session in 2021