Motors

ABB gets ahead of the game for Ecodesign regulation

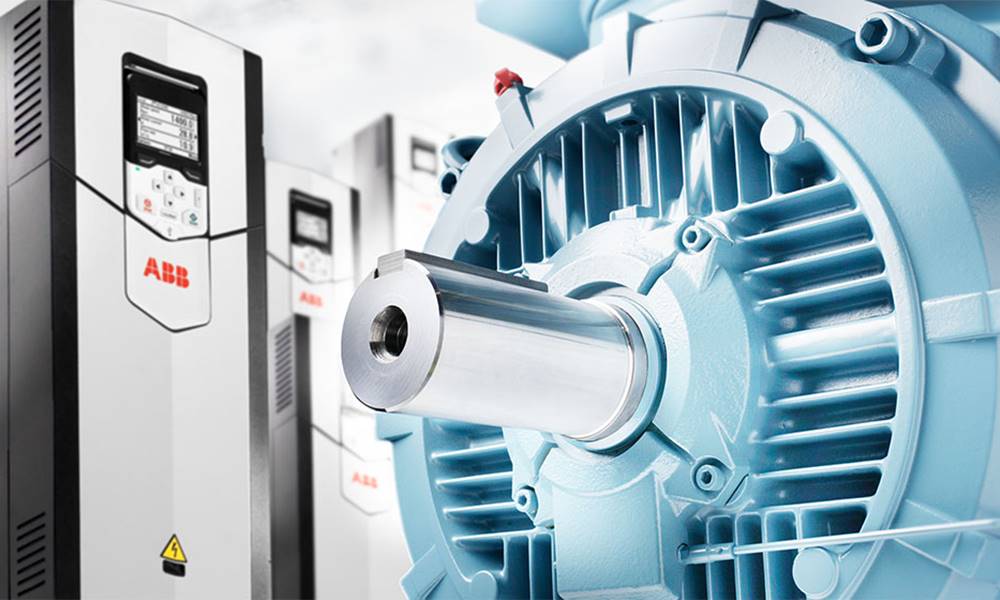

The European Union’s (EU) latest Ecodesign Regulation (EU) 2019/1781 came into effect in October 2019. This regulation sets new requirements from 2021 onwards for the energy performance of an expanding range of low voltage motors. For the first time variable speed drives (VSDs) are also included.

The aim is to contribute to the reduction of greenhouse gas emissions to limit the average global temperature increase to 1.5°C. Hannu Vaananen, Head of Public Affairs, Business Line Motors and Generators, shares some insights on what this regulation means for industrial electric motors.

The detail

The latest Ecodesign implementation applies to low-voltage induction electric motors – rated at less than 1,000 V alternating current (AC) – and variable speed drives (VSDs). While defining stricter minimum efficiencies, the regulation also expands the range of three-phase single speed motors covered from 0,12 to 1,000 kilowatt (kW). The same power range also applies to the drives.

The regulation only concerns the efficiency of standard VDSs. To allow to maximize savings on system level, regenerative and low harmonic drives have been excluded. On the motor side Ex and brake motors are now in the scope of the regulation.

The regulation will be implemented in two steps with the first starting on July 1, 2021. The second stage, which expands the scope further and increases the requirements for motors, commences two years later, on July 1, 2023. Super-premium-efficiency motors (IE4) will become mandatory for three-phase motors with 2, 4, or 6 poles between 75-200 kW.

What is the significance for industry?

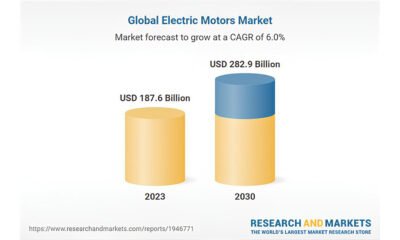

According to the International Energy Agency (IEA), electric motors account for 40% of total global electricity consumption, while industrial motors account for 30%. Lighting, a far better-known culprit, weighs in at just 19%. Using electric motors that offer the highest levels of energy efficiency can therefore play a crucial role in containing worldwide energy consumption and in reducing CO2 emissions.

So how is ABB helping this all-important cause?

We have pre-empted the new regulation as we can already provide our customers with compliant motors. This also applies to our variable speed drives – including the ACS880, ACH580, ACQ580, ACS 580, ACS480 and ACS380 product lines – as well as motor types that were previously exempt, such as Ex motors, Totally Enclosed Air Over (TEAO) motors, and motors for 60 Hz networks. Customers can, therefore, buy our products with full confidence.

One of the most affordable and effective ways to increase energy efficiency is to use VSDs in combination with high-efficiency motors. Our drives can reduce energy consumption by 30% to 50% by regulating the speed of, for example, the motor of a pump or fan. In extreme cases consumption can drop by 90%.

When it comes to new regulations, it’s essential to be ahead of the game as it ensures that customers have future-proof products. This is especially important as, on average, projects can take three years to move from the planning phase to the active phase.

Saving energy is a highly effective way to reduce greenhouse gas emissions and save money at the same time. That’s why we work with policymakers all the time to expand regulations that cover additional motors and drive systems. Our commitment is not only to our clients but also to a greener world.

-

Drive systems5 years ago

Drive systems5 years agoIntelligent frequency inverters for digital production

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoThe necessity of bolted flange connection training

-

Motors8 years ago

Motors8 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors8 years ago

Motors8 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives7 years ago

Gear drives7 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control7 years ago

Motion control7 years agoWhere the robots come from?

-

Motion control7 years ago

Motion control7 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES4 years ago

POWER TRANSMISSION TECHNOLOGIES4 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoCustom hobbing tool enables 45-degree angles