Industrial Hardware and Machine Parts

With INNOZL™ coolant nozzles to prevent grinding burn

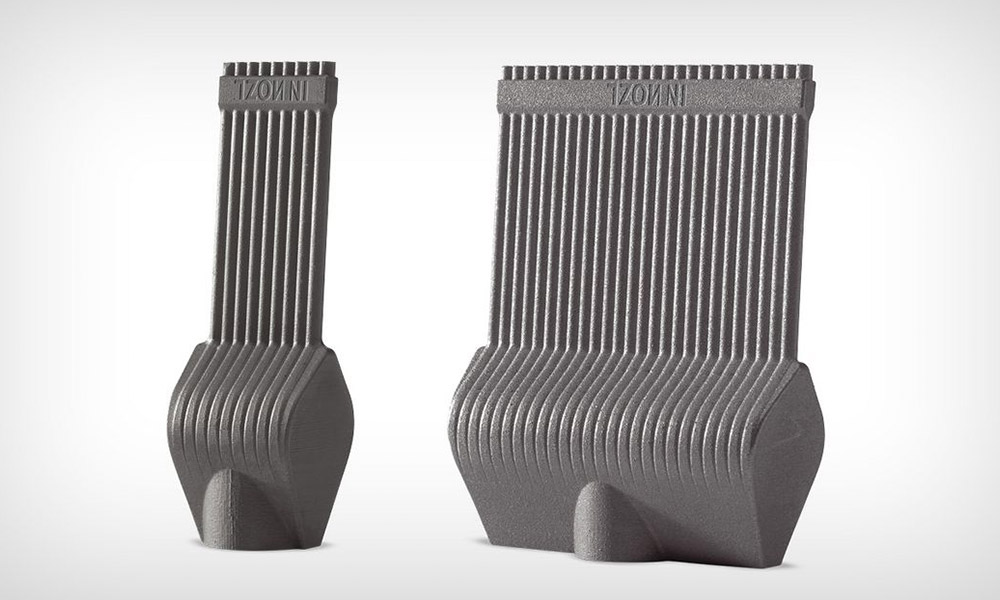

KNOLL assumes the entire product portfolio of the INNOZL™ coolant nozzles from the Dutch company INNOGRIND. The 3D-printed grinding nozzles made of titanium or stainless steel were developed specially for round, fl at as well as centreless grinding and reliably prevent thermal damage during the grinding process.

KNOLL Maschinenbau GmbH, Bad Saulgau, is one of the leading suppliers of grinding machines with its conveying and filter systems for chips and cooling lubricants. Matthias Knoll says: “With our tried-and-tested units in the machining process we ensure optimal grinding results and in particular high process reliability. We continue this commitment directly in the area of metal cutting with the takeover of the INNOZL™ coolant nozzles.”

KNOLL has been in contact with Jos van Langh

, founder and owner of Innogrind B.V., for many years. Grinding technology was always a common theme, something on which Jos van Langh has been concentrating for over 40 years. Apart from his consulting work for different companies, he developed specially designed coolant nozzles at the request of his customers to combat the dreaded grinding burn.

3D-printed and made of titanium or stainless steel, these INNOZL™ nozzles are superior to traditional plastic products in many respects: The geometry of the internal flow channel ensures that the coolant always reaches the contact zone uniformly both in terms of the flow rate and flow velocity and direction. The lubricant action is maximised and thermal damage to the workpiece is reliably prevented. With flow analyses these properties are examined and optimised with every new development. A resulting benefit: The nozzles operate almost without loss, whereby the flow rate required is lower and energy is saved.

In addition, the titanium and stainless steel nozzles are generally more resistant than their plastic counterparts and are also suitable for high-pressure applications. As a result, they can also be used as cleaning nozzles for ceramic CBN grinding discs. Their compact design is another benefi t. As a single-piece accessory they can be easily mounted on existing cooling systems.

“The INNOZL™ coolant nozzles are an ideal addition to our product portfolio”, highlights Matthias Knoll. They are supplied directly from stock as standard products INNOZL™ SL. KNOLL also develops customer- and process-specific INNOZL™ CL versions. The company can still count on Jos van Langh, who in future will also be responsible for the BeNeLux region as KNOLL Area Sales Manager.

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoThe necessity of bolted flange connection training

-

Drive systems6 years ago

Drive systems6 years agoIntelligent frequency inverters for digital production

-

Motors9 years ago

Motors9 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors9 years ago

Motors9 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives8 years ago

Gear drives8 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control8 years ago

Motion control8 years agoWhere the robots come from?

-

Motion control8 years ago

Motion control8 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES5 years ago

POWER TRANSMISSION TECHNOLOGIES5 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoCustom hobbing tool enables 45-degree angles