Events

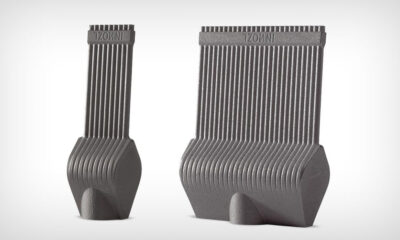

STUDER universal external grinding machines at a glance

FRITZ STUDER AG performing spectacular press event in Thun

A great deal has been written about the new favorit, S33 and S31 machines in recent months. The complete portfolio of STUDER universal external cylindrical grinding machines is presented in more detail in the following report.

From the entry-level machine for the main applications through to the all-rounder for complex grinding tasks. Small to large workpieces for individual, small-batch and large-scale production. With distances between centers of 400, 650, 1000 and 1600 mm and center heights of 175, 225 and 275 mm, STUDER offers the customer a selection of five universal cylindrical grinding machines.

favoritCNC – The well-known bestseller for the main applications

The favoritCNC is a CNC universal cylindrical grinding machine for the individual and batch production of medium-sized workpieces. It has distances between centers of 650 / 1000 mm and a center height of 175 mm. It can machine workpieces with a maximum weight of 80 / 120 kg. It can subsequently be easily adapted to other grinding tasks using various accessory kits such as in-process gauging, balancing system, contact detection and length positioning. The solid Granitan® S103 machine bed forms the basis for this cylindrical grinding machine, which is equipped with high quality components and guarantees maximum precision, performance and reliability over many years. The full enclosure ensures an optimal view of the grinding process.

favorit – The new bestseller for the main applications

The favorit is a CNC universal cylindrical grinding machine for the individual and batch production of short to long workpieces. It has distances between centers of 400 / 650 / 1000 / 1600 mm and a center height of 175 mm. It can machine workpieces with a maximum weight of 150 kg. This cylindrical grinding machine can be used universally and thanks to StuderPictogramming it is quick and easy to program. Its Granitan® S103 mineral casting machine base largely equalizes temporary temperature fluctuations. It can subsequently be easily adapted to other grinding tasks using various accessory kits such as in-process gauging, balancing system, contact detection and length positioning.

S33 – The good value solution for individual requirements

The S33 is a CNC universal cylindrical grinding machine for individual, small-batch and large-scale production of small to large workpieces. It has distances between centers of 400 / 650 / 1000 / 1600 mm and a center height of 175 mm. It can machine workpieces with a maximum weight of 150 kg. It can be changed over from grinding between centers to live grinding in record time. You can grind even complex workpieces in a single clamping: This is made possible by the new wheelhead head with two motor spindles. The foundation is the solid Granitan® S103 machine base.

S31 – The versatile solution for large tasks

The S31 is a cylindrical grinding machine for individual, small-batch and large-scale production of small to large workpieces. It has distances between centers of 400 / 650 / 1000 / 1600 mm and a center height of 175 mm. It can machine workpieces with a maximum weight of 150 kg. Thanks to the expandable modular system the S31 can be precisely adapted to the customers’ requirements. With a high-resolution B-axis of 0.00005°, the swiveling wheelhead enables external, internal, and face grinding in a single clamping. The foundation is the solid Granitan® S103 machine base.

S41 – The all-rounder for complex grinding tasks

The S41 is a CNC universal cylindrical grinding machine for large workpieces. It has distances between centers of 1000 / 1600 mm and center heights of 225 / 275 mm. It can machine workpieces with a maximum weight of 250 kg. The S41 has a host of sophisticated technical features such as the revolutionary StuderGuide® guideway system, high-precision axis drives with linear motors, extremely fast B-axis direct drive, an even wider selection of wheelhead variants and much more.

-

Drive systems4 years ago

Drive systems4 years agoIntelligent frequency inverters for digital production

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoThe necessity of bolted flange connection training

-

Motors7 years ago

Motors7 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors7 years ago

Motors7 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives6 years ago

Gear drives6 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors7 years ago

Motors7 years agoGet a first-class ticket to productivity

-

Motion control6 years ago

Motion control6 years agoWhere the robots come from?

-

Motion control6 years ago

Motion control6 years agoRexnord to Acquire Centa Power Transmission

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoCustom hobbing tool enables 45-degree angles

-

POWER TRANSMISSION TECHNOLOGIES3 years ago

POWER TRANSMISSION TECHNOLOGIES3 years agoEUROTRANS Board meets for its first session in 2021