Linear Motion Devices

WDS is expanding its conveyor components range

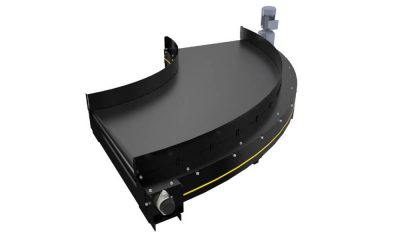

The UK’s leading supplier of engineering components, WDS Components Parts Ltd. is expanding its range of conveyor parts, with new guide rails, bracketry, bearing mountings and guides. These will complement the existing skate wheels, omni-wheels, support bases, connecting joints, mounting brackets, head mounts and clamps.

“With the newest additions, WDS now offers a complete set of elements for the building, extension, maintenance and repair of materials handling systems,” Adrian Wells, Product Manager at WDS explains.

“Typically, we supply conveyor parts to two types of customer: end users and specialist conveyor design and build firms. The latter make the main conveyor beds complete with powered rollers and/or drives. Of course, many sectors use conveyors, so we have built a portfolio of products that can serve a wide range of users, including manufacturing companies, food processors, pharmaceuticals producers, electronics specialists, parcel and package distributors. The conveyors are also suitable for end-of-line operations, such as packing, stacking, palletising and transfer in any industry.

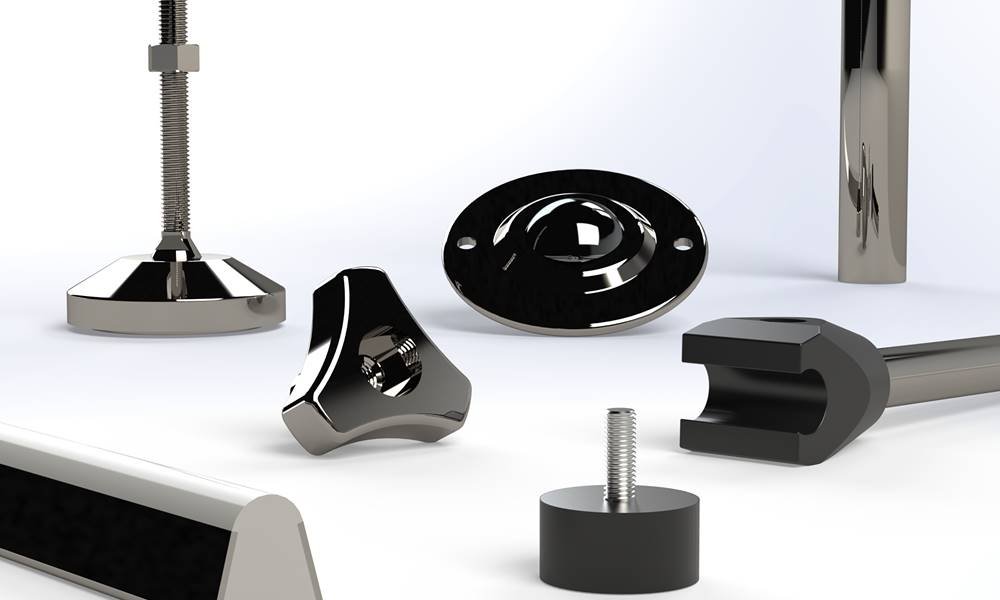

In addition to supplying a full suite of components parts, WDS simplifies the procurement process by offering a comprehensive online catalogue that features technical data, 3D CAD models and one-click ordering for all of its standard parts. Each component is available in a range of sizes, with options for variations such as shaft lengths, choice of handle type and metric or Imperial screw thread options. It also offers products in a range of materials, such as stainless steel for clean and hygienic environments, aluminium for weight sensitive applications, or plastics and ceramics as an alternative to steel, etc.

Its conveyor products are further supported by the full range of standard engineering parts such as fastenings, hinges, clamps; footings, mounts, casters and wheels; shafts and joints; levers, knobs, handles and hand wheels; locating pins, locks and latches. All of these are supported by the layers of technical help WDS makes freely available via its website (www.wdsltd.co.uk), telephone help line (08456 066677), email communications and on-line videos.

WDS’ headquarters combines a stock holding and dispatch centre with on-site manufacturing so that it can offer a bespoke service to customers that require special products rather than standard components. Thanks to this set up it is able to offer next day delivery on 98% of standard orders and extremely fast turnaround of bespoke orders.

Adrian explains the advantage of this: “Typically a conveyor system will be made up almost completely of standard components, but there may be a need for a customised bracket, special mounting or similar. At WDS we are able to produce these little extras and save our client all the effort of finding and dealing with a third party for just one or two parts.”

-

Drive systems4 years ago

Drive systems4 years agoIntelligent frequency inverters for digital production

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoThe necessity of bolted flange connection training

-

Motors7 years ago

Motors7 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors7 years ago

Motors7 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives6 years ago

Gear drives6 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors7 years ago

Motors7 years agoGet a first-class ticket to productivity

-

Motion control6 years ago

Motion control6 years agoWhere the robots come from?

-

Motion control6 years ago

Motion control6 years agoRexnord to Acquire Centa Power Transmission

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoCustom hobbing tool enables 45-degree angles

-

POWER TRANSMISSION TECHNOLOGIES3 years ago

POWER TRANSMISSION TECHNOLOGIES3 years agoEUROTRANS Board meets for its first session in 2021