Motors

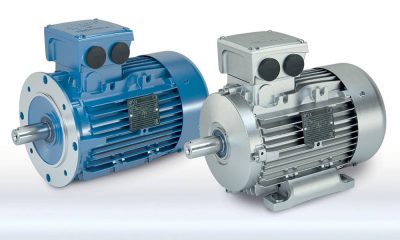

Time for efficiency in electric motors with Voltpro series

In this issue we interviewed Mr. Ferudun Özdemir, Director of Sales and Marketing, Volt Electric Motors. As we leave you alone with this interview, we would like to thank the Volt Motor family and Mr. Ferudun who hosted us and answered our questions at Volt Motor stand in ISK SODEX 2018.

Can you shortly describe your company?

Founded in 1966 to produce coils, Volt Motor also started to produce mono-phase electric motors and later tri-phase electric motors as of 1987, taking its place in the electric motor sector.

Volt Motor became an associate of Saya Group in 2011. With 45,000 sqm of production area and more than 500 employees Volt Motor has achieved a product portfolio reaching from type 63 bodies to type 315 bodies and up to 200 kW in power in result of investments in new technology and R&D.

Today, Volt Motor has become one of the largest electric motor producers in Turkey.

As Volt Motor we introduced electrical motors in IE3 efficiency class, the premium energy level, in result of pioneering R&D studies we conducted in order to decrease national energy consumption and to increase energy efficiency. We also produced motors in IE4 class, super premium energy level, with our own R&D efforts and under our own patent.

On the other hand we started producing the most efficient motor of the world with our newest technology and compact series product Voltpro, and we started to offer this product in domestic and international markets.

Celebrating its “30th anniversary” in 2017, the aim of Volt Motor is to continue growing and developing in Turkey, its main market, and to increase its exports to Germany in main as well as other European countries and Middle Eastern countries, on its way to taking its place among top 500 industrial companies of Turkey.

Growing rapidly, Volt Motor continues its journey towards excellence, towards becoming a global company, under guidance of TURQUALITY and EFQM, with world level product and service quality and sustainable success goals.

In scope of its year 2023 vision, Volt Motor advances towards “Powered by Volt” mission with firm steps on the way to its goal to create a “content brand”.

What are the products and services you offer to your clients?

As Volt Electric Motors we produce Asynchronous Motors. We produce two types, comprising mono-phase and tri-phase motors. Our mono-phase models range from type 71 to type 100 bodies and from 0.18 kW to 3 kW in power. Our tri-phase models range from type 60 to type 315 bodies and from 0.18 kW to 200 kW in power. Again, in line with the recent popularity of innovative products, we also started to produce magnetic synchronous motors. This later product is especially targeted towards foreign clients. In addition, now we also offer our new driver application, introduced in Sodex 2018, to our clients through both sales and technical services channels.

Which are the main sectors you provide solutions in?

As electric motors are the initial drive for all revolving mechanisms, as well as providing an element converting electric power into kinetic energy, they are widely used in all fields of industry. Volt Motor provides solutions in many sectors, mainly comprised of pump sector, compressor sector and power transmission and reducer sectors, as well as the agricultural sector where Volt Motor holds more than 50 percent market share in mono-phase motors, and the air conditioning sector which is the subject of the Sodex Expo. Of course, as I mentioned above, our products are used in all fields of the industry.

Can you tell us about your sales and after-sales services?

We conduct our sales through our dealers. We provide our products to our clients through our dealers at every point of Turkey, especially in metropolises where industry is concentrated. In addition to our commercial dealers we also have OEM vendors that buy our products and sell them on the market alongside their own products. They are also large producers in sectors like pump and compressor sectors. We use the OEM sales channel more in foreign areas. We receive more demand for our technologic know-how from foreign clients, therefore the foreign markets, especially Germany is our largest export destination where we concentrate our sales and after-sales service efforts.

What would you like to say about energy efficiency in electric motors?

As you know energy efficiency became mandatory by regulation as of 2012 in the electric motors sector. The Turkish Ministry of Industry made it compulsory to produce and sell electric motors up to IE2 standards in 2012, simultaneously with Europe. The schedule ran like this: production and sale of motors up to IE2 standard would become compulsory as of April 2012. Approximately 3 years after that, in 2015, compliance with IE3 standards became compulsory for electric motor production. This became a requirement for motors above 7.5 kW of power. Similarly, the requirement to comply with IE3 standard in production of motors of 0.75 kW and above in power entered into force on 01 January 2017, in tandem with Europe. Of course we had already made our preparations towards this eventuality in 2012. Currently we are developing our IE4 motor production line with our magnetic series which exceed IE3 requirements. Especially, most of our export volume is comprised of IE4 and higher motors. Even though efficiency development is not as quick as Europe in Turkey, we also offer our IE3 motors in Turkey.

Can you review ISK Sodex Expo for your company?

As Volt Motor we are participating in Sodex Expo for the first time this year. This is the most important exposition event in this sector. It is the most important exposition event in pump and air conditioning sector in Europe and in Turkey. We are very satisfied with this event. We made substantial business partnerships. We have a new demo presenting our new series and the interest it garnered made us very happy. It looks like we will be a constant participant of this event. Both the quality of visitors and the value and care the participants clearly give to the event point out the importance of this exposition. There are many foreign visitors at the event. I never saw an event with so many foreign participants in Turkey before. People attend from all over the world.

Can you evaluate sector development in scope of Industry 4.0?

The sector is interested in embracing innovative products, especially in case of technologic products. The Turkish market is not culturally very used to technology, but we wish to be a pioneer on this front. Electric motor was invented by Nicola Tesla in 1800s, but it has been produced and sold on the same technology for about 150 years. While their contribution to the sector is very large, the energy conversion efficiency of electric motors is substantially low. We wish to overcome this shortcoming with our newly developed magnetic motor series.

Voltpro magnetic synchronous motor series with permanent magnets is a new industrial motor range developed to meet the need in IE4 and higher energy efficiency classes. The greatest advantage of Voltpro product range is the fact that it provides a cost efficient solution by using ferrite magnets in the rotor. Combining fundamental characteristics of two different motor technologies in the motor design, we developed products above IE4 efficiency class with vector drive method. The magnetic circuit of the rotor is designed to create both magnetic and reluctance moment in the motor at the same time.

The magnets are placed in lamination, in a configuration providing suitable projection between d and q axes of the motor.

Major diameter coiling technology is used on stators in order to decrease coil end heights and thus minimise copper loss. As you know major diameter coiling causes high moment fluctuations. These fluctuations are decreased to a level under 15% with magnetic circuit design.

In order to provide high efficiency and suitable moment speed characteristic in all motor applications (pump, fan, compressor, transport, etc.) the motor EMF waveform is in sinusoidal form in line with FOC control. In case of variable speed applications using speed control devices the IE1-IE2-IE3 efficiency class motors can be replaced with Voltpro PMSM series products without any additional cost to provide high gains in system efficiency.

Can you share the projects you intend to implement in the short- and long-term?

Our vision is to produce what is not yet produced but imported in Turkey. This is our starting point. Currently we sell imported drivers, but we plan to combine all elements in the future. First we will learn to sell, then we will try to make. There is a product called servo motor, which is not produced in Turkey, but has a significant consumption. We are taking middle-term steps to produce this type of product. We also have a vision to potentially produce electric car motors. Electric motors might be useless on their own in regard of industry, but they are also the lifeblood for many applications. Our future vision is one we symbolise with the slogan “Powered by Volt”. We hope one day users of pump, compressor or any electric motor application will see and seek the mark “Powered by Volt”. We have our short- and middle-term strategies ready towards this goal.

Would you like to give some last remarks?

The Ministry of Economy has a stimulus program named TURQUALITY, especially targeting export companies for creation of international brands. We can refer to this as a champions’ league of industry, supporting companies seeking the dream of becoming international brands. TURQUALITY is a stimulus program providing significant contributions for corporate and brand development of companies. We are the first and only company to apply for this program from the electric motor sector. After a 4 year preparation period we had our first round of inspections and we are currently waiting to hear the results from the Ministry.

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoThe necessity of bolted flange connection training

-

Drive systems6 years ago

Drive systems6 years agoIntelligent frequency inverters for digital production

-

Motors9 years ago

Motors9 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors9 years ago

Motors9 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives8 years ago

Gear drives8 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control8 years ago

Motion control8 years agoWhere the robots come from?

-

Motion control8 years ago

Motion control8 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES5 years ago

POWER TRANSMISSION TECHNOLOGIES5 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoCustom hobbing tool enables 45-degree angles