Events

New machine builds on successful IMSA-NSK partnership

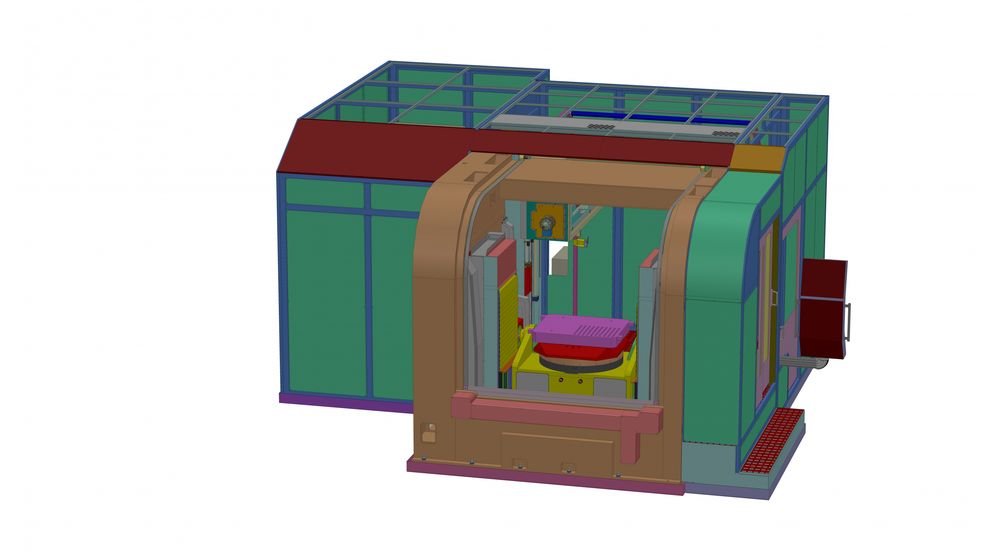

The new MF1000-3T deep-hole drilling machine from IMSA is taking advantage of the benefits provided by NSK’s DIN-standard ball screws for the European machine tool market. The move builds upon a long-standing partnership between IMSA and NSK that dates back many years and involves the development of numerous machine models. IMSA intends to show the new MF100-3T at the EMO Milano machine tool exhibition in October 2021.

Established in 1988, IMSA is located in Barzago, northern Italy, from where core business centres on the design and manufacture of deep-hole drilling and gun-drilling machines. As a leader in its field, there are now more than 500 such IMSA machines operational worldwide.

Applications are wide and varied, but many focus on the gun drilling of mould tools for the automotive industry. Seven IMSA models for this purpose came to market between 2014 and 2019 alone. Thanks to a series of options, each standard base model is custom-built according to the specific requirements of customers, although the company can also design and manufacture completely bespoke solutions.

To help maximise machine performance, IMSA has for many years relied upon ball screws and linear guides from its preferred linear motion partner, NSK. The company is now repeating this tried and tested formula for its latest deep-hole drilling machine, the MF1000-3T, which will be able to produce holes up to 1000 mm deep (depending on tooldiameter). Equipped with a tilting head, the machine will also offer the capability to perform milling operations, while an 80-station automatic tool-change magazine and automated pallet changer will facilitate unattended workpiece machining.

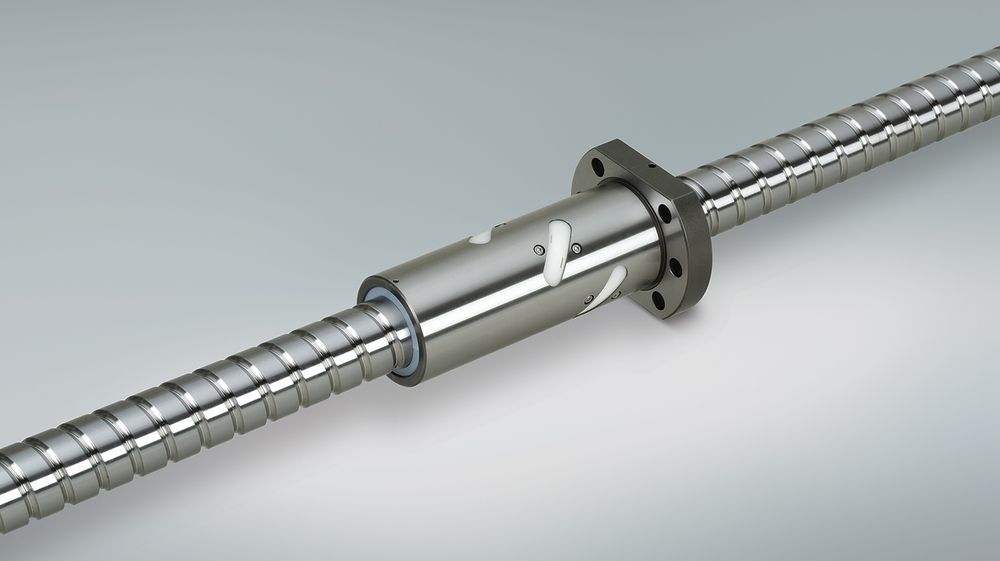

NSK’s ball screw, which conforms to DIN 69051 (ISO 3408) with regard to both dimensional and tolerance classes, meets IMSA’s performance demands in term of speed, accuracy, load capacity and rigidity. The first NSK DIN-standard ball screw order is due for delivery in May 2021 to meet the requirements of a prototype MF1000-3T. NSK RA65 roller guides will also form part of the order.

Manufactured in shaft diameters from 32 to 63 mm, and with leads from 10 to 40 mm, NSK DIN-standard ball screws offer a speed factor of 160,000 dn. This performance level makes them ideal for use without restriction in high-speed machining applications where very accurate positioning is also required. In addition, the smooth running properties of the ball screws incur the least possible vibration in the linear system, while simultaneously reducing noise levels.

-

Drive systems4 years ago

Drive systems4 years agoIntelligent frequency inverters for digital production

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoThe necessity of bolted flange connection training

-

Motors7 years ago

Motors7 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors7 years ago

Motors7 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives6 years ago

Gear drives6 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors7 years ago

Motors7 years agoGet a first-class ticket to productivity

-

Motion control6 years ago

Motion control6 years agoWhere the robots come from?

-

Motion control6 years ago

Motion control6 years agoRexnord to Acquire Centa Power Transmission

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoCustom hobbing tool enables 45-degree angles

-

POWER TRANSMISSION TECHNOLOGIES3 years ago

POWER TRANSMISSION TECHNOLOGIES3 years agoEUROTRANS Board meets for its first session in 2021