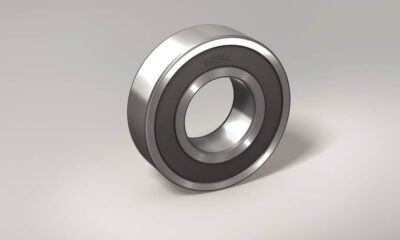

Bearings

Michell Bearings’ unique capability a success for nuclear station blackout

Michell Bearings has successfully completed station blackout (SBO) tests on a thrust and guide bearing used within the reactor coolant pump at a new build nuclear power plant.

In what is thought to be one of the world’s first successful bearing run downs, the test demonstrated the bearing’s ability to survive a station blackout condition without the use of an externally powered high pressure oil injection system.

Failure of the on-site power generators concurrent with the loss of offsite power ultimately results in a station blackout condition as there is no on-site electricity available to power the high pressure oil injection system.

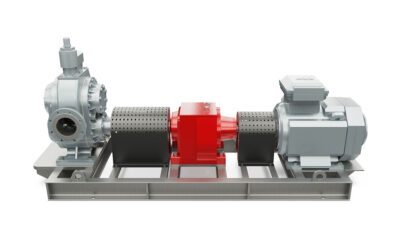

In order to meet testing requirements, the bearing must be able to run down to a stop, under full load, and restart without any subsequent intervention. As part of the contract to supply six thrust and guide bearings, a custom made test rig was constructed at the Michell Bearings site in order to satisfy the test conditions.

The test rig was designed to closely replicate real world bearing operating conditions such as the possibility of a station blackout, where the bearings are required to shut down safely without the aid of electrical power to drive the reactor coolant pumps.

Paul Bruce, Engineering Director at Michell Bearings, said: “We were delighted to be able to provide a solution to satisfy such challenging conditions. This is testament to the operation of our bearings, along with our high levels of research and development.

“Damage to the working surfaces of the tilting thrust pads is not permitted. The combination of full thrust load and very slow rotational speeds over a sustained period results in the bearing operating under very low oil film thicknesses. Consequently, special design considerations are required to survive such a condition.”

The bearings were designed, manufactured and tested at the Michell Bearings manufacturing site based in Newcastle upon Tyne, UK. This latest success comes after Michell Bearings developed and successfully station blackout tested a set of thrust internals with a leading European reactor coolant pump manufacturer in 2018.

-

Drive systems4 years ago

Drive systems4 years agoIntelligent frequency inverters for digital production

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoThe necessity of bolted flange connection training

-

Motors7 years ago

Motors7 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors7 years ago

Motors7 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives6 years ago

Gear drives6 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors7 years ago

Motors7 years agoGet a first-class ticket to productivity

-

Motion control6 years ago

Motion control6 years agoWhere the robots come from?

-

Motion control6 years ago

Motion control6 years agoRexnord to Acquire Centa Power Transmission

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoCustom hobbing tool enables 45-degree angles

-

POWER TRANSMISSION TECHNOLOGIES3 years ago

POWER TRANSMISSION TECHNOLOGIES3 years agoEUROTRANS Board meets for its first session in 2021