Belt and Belt Drives

Interroll’s second plant in Atlanta starts operation

Interroll has completed construction on its second plant on their campus in Hiram (Atlanta) Georgia. The 11 million dollar investment gives Interroll a substantial increase in capacity for the region.

At Interroll, the Americas region continues to see a high level of project activities. At the same time, the company is quickly introducing innovative solutions to the markets. Key business drivers such as increased automation for warehouses as well as the rise of e-commerce and high demand in the courier, express and parcel business continue to support this positive mid-term outlook in the Americas region and worldwide.

“We have raised capacities in order to ensure low lead times for our customers and end users in the North American market in the years to come”, says Richard Keely, Executive Vice President of the Americas region and member of the Group Management. “We continue to see high demand for Interroll solutions in the areas of conveyors and sorters. Therefore we have increased our fabrication footprint while creating several new lean agile assembly cells.”

The new building provides 100,000 sq ft (9,300 m2) of manufacturing and warehousing area are as well as 25,000 sq ft (approx. 2,300 m2) of offices. It also includes training facilities as well as a Kaizen room and employee facilities such as a gym.

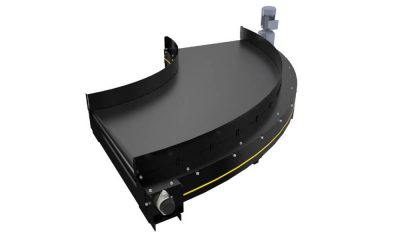

The new building provides assembly lines for the Modular Conveyor Platform (MCP), as well as for all sorters, including the new high-performance crossbelt sorter (HPCS) as well as sorter chutes. In the near future, it will also house a production line for Modular Pallet Conveyor Platforms (MPP).

“Over the last few months, capacity is more and more critical as supply chains are challenged with lockdowns and other restrictions. Through this challenging period, we have continued to see new opportunities because of our commitment to short delivery times” says Keely. “Our team is fully committed to keeping this climate of excellence and looks forward to convincing more customers with our delivery performance in the future.”

-

Drive systems4 years ago

Drive systems4 years agoIntelligent frequency inverters for digital production

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoThe necessity of bolted flange connection training

-

Motors7 years ago

Motors7 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors7 years ago

Motors7 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives6 years ago

Gear drives6 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors7 years ago

Motors7 years agoGet a first-class ticket to productivity

-

Motion control6 years ago

Motion control6 years agoWhere the robots come from?

-

Motion control6 years ago

Motion control6 years agoRexnord to Acquire Centa Power Transmission

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoCustom hobbing tool enables 45-degree angles

-

POWER TRANSMISSION TECHNOLOGIES3 years ago

POWER TRANSMISSION TECHNOLOGIES3 years agoEUROTRANS Board meets for its first session in 2021