Belt and Belt Drives

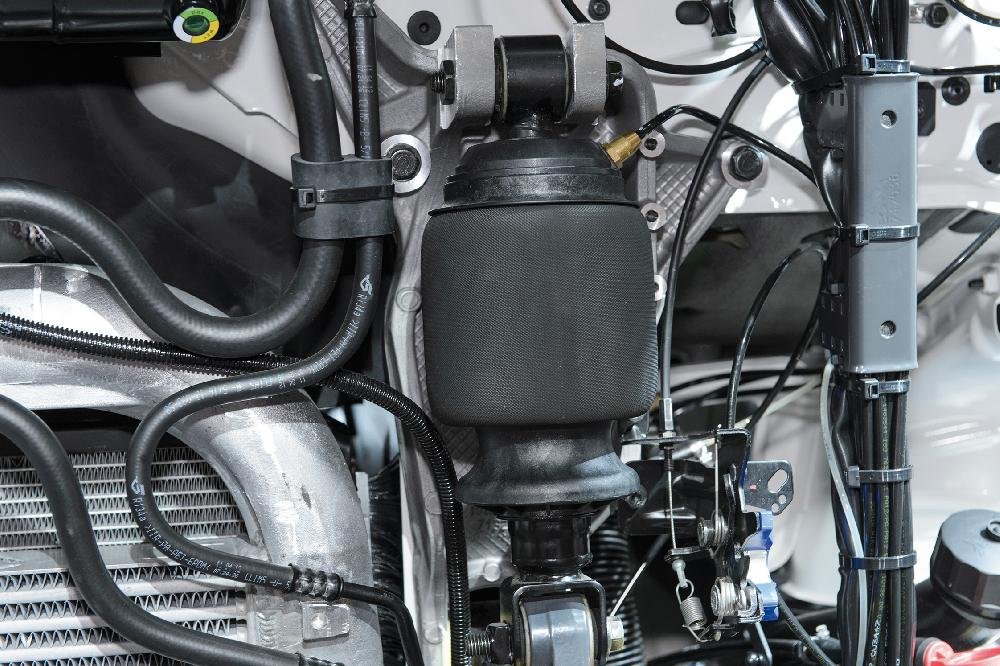

HiTemp air springs for suspension of truck cabs

Technology company Continental is taking an important step in the direction of an industry standard with its HiTemp air springs. A well-known Swedish commercial vehicle manufacturer is equipping as standard all of its truck driver’s cabs with sleeve air springs, which can easily withstand temperatures between -40 and +100 degrees Celsius. The project is being implemented in close collaboration with a market-leading shock absorber manufacturer.

Truck drivers often cover vast distances – not to mention the vehicles that experience a wide range of different regions and climate zones over their service life. To ensure that the driver’s cab is kept safe and comfortable both in the winter cold of Scandinavia or Russia, as well as in the summer heat of Spain, North Africa, or even in southern Asia, Continental has developed the HiTemp solution, which performs reliably even under extreme temperatures.

The air springs meet the increasing demands on truck components: the stricter exhaust-gas standards heat up the engine compartment to a much greater extent, ensuring extremely hot operating conditions. The advantage of the sleeve air springs: they allow for easier heat management and offer the manufacturer greater flexibility when defining the installation space of the cab mount. There is no need for a heat shield to protect the air springs against intense heat radiation. This makes the spring function significantly cheaper than previous solutions – reduced idle time and lower repair costs are further advantages.

Temperature resistance is becoming increasingly important in a global world

“The fact that from now on our customer will be installing our temperature-resistant model of sleeve air spring in its entire truck fleet as standard is not just confirmation of our strategy of bringing this product into focus for our partners and customers. It is also an important step on the way to establishing the HiTemp sleeve air spring as the standard in the commercial vehicle industry,” says Holger Brüning, head of air spring systems for commercial vehicle original equipment at Continental. “The sleeve air springs for extreme temperatures not only ensure significant improvements in use at high temperatures, but also increase the permissible range at minus temperatures. In addition, the sleeve can withstand an extreme long-term stress.”

Holger Brüning, head of air spring systems for commercial vehicle original equipment at Continental.

In addition to the innovative rubber compound that forms the basis of the sleeve air spring, which is based on high-temperature elastomers for high-performance bonds in terms of dynamic resilience and thermal resistance, the enhanced manufacturing process in the Hanover-Vahrenwald plant is crucial for the improved performance. “In the future, we will see great demand for our HiTemp air springs, and the demand will continue to grow. This is why we are also systematically investing in our production processes and continuously expanding our production capacity,” says Brüning.

-

Drive systems5 years ago

Drive systems5 years agoIntelligent frequency inverters for digital production

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoThe necessity of bolted flange connection training

-

Motors8 years ago

Motors8 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors8 years ago

Motors8 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives7 years ago

Gear drives7 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control7 years ago

Motion control7 years agoWhere the robots come from?

-

Motion control7 years ago

Motion control7 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES4 years ago

POWER TRANSMISSION TECHNOLOGIES4 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoCustom hobbing tool enables 45-degree angles