Genel

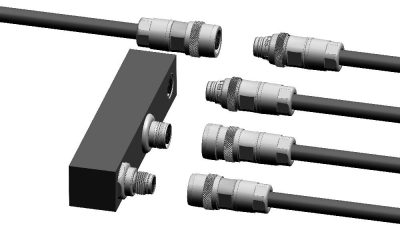

HARTING supplies cable assemblies for medical devices

Protection of employees and delivery capability takes utmost priority

Against the backdrop of the coronavirus pandemic, the HARTING Technology Group has taken numerous measures to protect its employees on the one hand, while ensuring that customers continue to benefit from a reliable supply of HARTING products and solutions on the other. “The protection of employees, but also maintaining the supply chain, is our top priority,” as Philip Harting, CEO of the HARTING Technology Group underscored. HARTING supplies renowned manufacturers of medical and respiratory equipment with customer-specific cable assemblies.

Working under high pressure, several German manufacturers are currently producing the devices on which patients and doctors are urgently dependent in the coronavirus pandemic. HARTING has aligned its internal processes so as to supply these medical device manufacturers as quickly as possible. For years now, HARTING has been manufacturing complete connectivity system solutions for these devices. The current high and short-term requirements and the maintenance of the associated supply chain present major challenges for all parts of the company. At HARTING, securing the supply of the required components takes priority over all other activities.

Extensive rules of conduct and hygiene

All manufacturing, storage and delivery functions are secured by separation in space and time as well as a multitude of hygiene measures. Where expedient and sensible, many employees are already working from their home office. In addition, HARTING started to ramp up its stock levels weeks ago in order to be able to respond in the best possible way to any supply chain disruptions. Specially formed back-up teams serve to safeguard key areas when necessary.

A corona task force and a pandemic team coordinate all necessary measures.

“We are experiencing something that is absolutely unprecedented in this form. And we don’t know when the nightmare of the ‘Corona pandemic’ will end and what challenges still lie ahead. One thing is certain, we are doing everything we can to protect our employees and help our customers wherever possible,” Philip Harting went on to emphasize.

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoThe necessity of bolted flange connection training

-

Drive systems6 years ago

Drive systems6 years agoIntelligent frequency inverters for digital production

-

Motors9 years ago

Motors9 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors9 years ago

Motors9 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives8 years ago

Gear drives8 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control8 years ago

Motion control8 years agoWhere the robots come from?

-

Motion control8 years ago

Motion control8 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES5 years ago

POWER TRANSMISSION TECHNOLOGIES5 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoCustom hobbing tool enables 45-degree angles