Motors

ZF Next-Generation Asynchronous E-Motor (ASM) Enters Mass Production in China

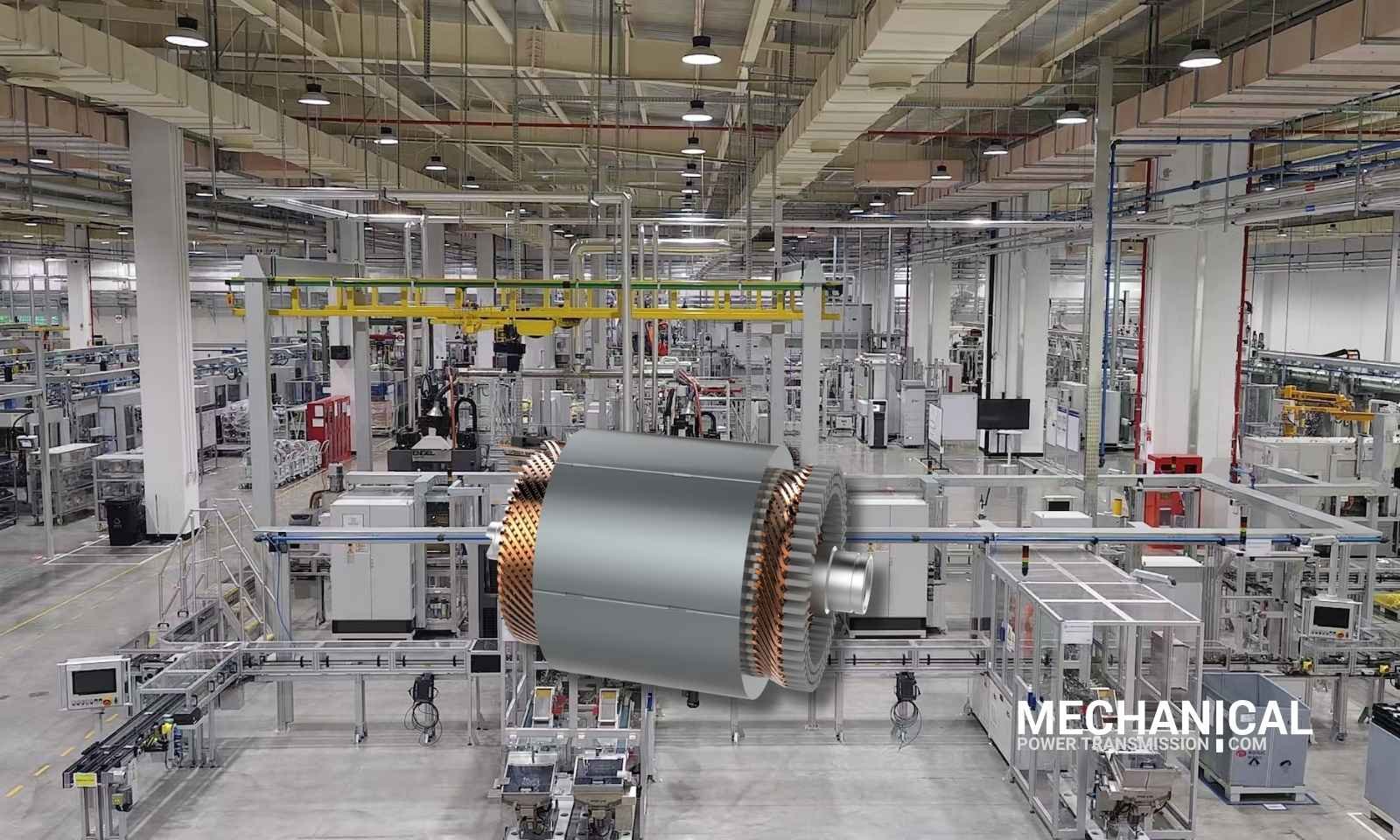

ZF next-generation platform-based Asynchronous E-Motor has officially entered mass production in China. This E-motor is engineered to deliver high performance, enhanced efficiency, and cost-effective manufacturing. Leading car manufacturers are set to incorporate this E-motor into their upcoming EV models to be launched in China.

Hangzhou, China. In June, ZF has officially launched mass production of its next-generation asynchronous electric motor at ZF Electrified Powertrain Technologies (Hangzhou) Co., Ltd. It is the result of ZF’s new platform approach allowing for more agile customer adaptation, accelerated market entry, and scalable manufacturing within competitive cost structure.

“This marks another important milestone in our local e-mobility strategy,” says Timo Maisel, Senior Vice President of Electrified Powertrain Technology Division, Asia Pacific. ”With its innovative design and optimized production process based on our platform strategy, this electric motor delivers everything that matters to automotive manufacturers — which is positively reflected in our order books in China.

Thanks to advanced manufacturing techniques, the motor achieves high power density and a quieter, more refined driving experience. Its cost-efficient production gives automakers a competitive edge in the fast-growing EV market.

The Hangzhou plant, a benchmark for Industry 4.0, combines robotics, intelligent logistics, and rigorous quality control to ensure high-volume output without compromising standards.

The technology will be integrated by Chinese car manufacturers, who are emerging as pivotal partners in scaling up production and advancing electric mobility.

“The strategic alignment and co-development with major car manufacturers ensure demand stability and opens the door for supplier partnerships. ZF is certainly willing to grow together closely with our customers,” said Mao Ziqian, Head of Product Line Powertrain Modules & Electric Motors AP. “ZF follows the market demand and forms strategic synergies and joint development with major automakers to ensure high quality and stable supply, and at the same time creates more opportunities for in-depth cooperation in the supply chain to promote the upgrading and development of the entire electric mobility ecosystem.

By combining advanced rotor technologies such as ASM, PSM, and SESM with a globally standardized stator production system, the new electric motor platform em:SELECT enables ZF to tailor e-motors precisely to customer requirements. This platform approach not only accelerates time-to-market but also ensures that future innovations can be seamlessly integrated.

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoThe necessity of bolted flange connection training

-

Drive systems6 years ago

Drive systems6 years agoIntelligent frequency inverters for digital production

-

Motors9 years ago

Motors9 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors9 years ago

Motors9 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives8 years ago

Gear drives8 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control8 years ago

Motion control8 years agoWhere the robots come from?

-

Motion control8 years ago

Motion control8 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES5 years ago

POWER TRANSMISSION TECHNOLOGIES5 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoCustom hobbing tool enables 45-degree angles