Motion control

TRANSCYKO is the choice for RGV

Leader AGV and RGV companies’ choice has become Transcyko cycloidal drives for the reason of cost-efficient solutions and its added value over long term.

Transcyko drive systems support their customers to reduce manufacturing costs and keep the heights in competition in the market.

Transcyko drive engineering specialists offer solutions & expertise for virtually any automated transportation challenge on the plant floor. They have over two decades of expertise developing highly efficient, high speed, durable and cost-effective drive solutions for plant transportation systems across the USA.

Robustness, Trust & Easy Maintenance

Drives are also designed for rapid maintenance with a fast and flexible drive assembly process. They have support locations coast to coast, so they are always there when you need them. They also gurantee that drive designs feature modular components that can be rapidly delivered.

In Transcyko, system’s uptime’s importance is customer’s success. That’s why they build reliable products to industry standards and offer modular drive components for quick delivery; fast and flexible drive assembly processes; support locations coast-to-coast and committed staff near the customer who will do whatever it takes to keep them up and running with the shortest down time possible.

What Are Rail Guided Vehicle (RGV) Systems?

RGV Systems are fast flexible rail systems which make it possible to transport large quantities of heavy good over long distances at low cost with high efficiency.

RGV systems are vital for Storage, Handling, and Order fulfillment in a wide range of industries. Due to their widespread application, they are also seen as mission critical to daily operations for many large industrial plants.

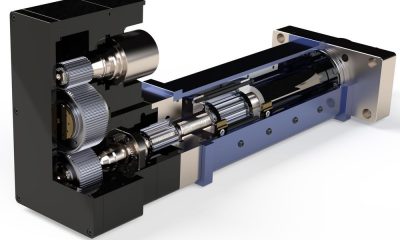

This means that the reliability of the drive and control systems for these RGV systems is key to their overall operation efficiency and productivity. Transcyko produces the high reliability cycloidal drives which are used in these rail guided systems.

RGV Systems’ Advantages

RGV Systems are easily installable, highly scalable and easily maintainable. In all systems, the vehicles can easily be removed and replaced for maintenance or upgrade without affecting the overall operation of the system.

The patterns which the systems shall be installed can be linear or circular. It’s dependent on the position and manufacturing necessities.

-

Drive systems5 years ago

Drive systems5 years agoIntelligent frequency inverters for digital production

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoThe necessity of bolted flange connection training

-

Motors8 years ago

Motors8 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors8 years ago

Motors8 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives7 years ago

Gear drives7 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control7 years ago

Motion control7 years agoWhere the robots come from?

-

Motion control7 years ago

Motion control7 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES4 years ago

POWER TRANSMISSION TECHNOLOGIES4 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoCustom hobbing tool enables 45-degree angles