Gear Manufacturing Services

Reliable thread turning in tight spaces

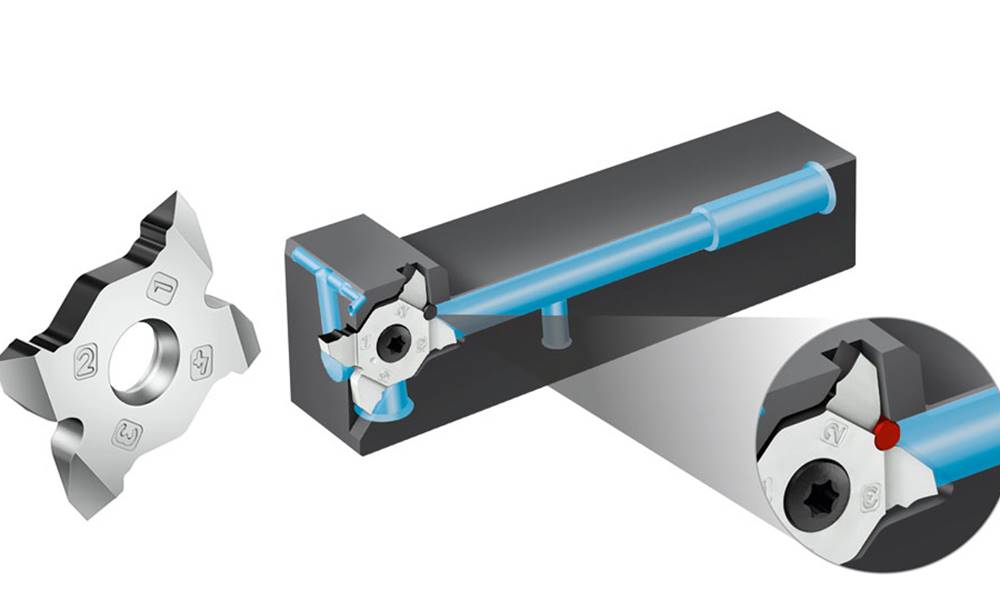

Walter AG is completing its range of MX grooving inserts with the A60 and AG60 geometries for small to medium pitches. Just like the existing MX geometries (CF5 and GD8 for all grooving and parting off tasks, RF5 for grooving and copy turning), the A60/AG60 inserts are also designed with four cutting edges.

The geometries are made for creating 60° partial-profile external threads in a wide range of pitches (0.5–3.0 mm) and are particularly suited to thread turning in tight spaces, like near a shoulder or counter spindle. In addition, the system offers general advantages like excellent cost-effectiveness or the ability to use all inserts universally with one toolholder on the left and right.

The MX system is suitable for all materials and enables insert widths between 0.8 and 3.25 mm and cutting depths of up to 6 mm. One special feature is the design of the insert seat: Due to the self-aligning tangential clamping, the insert is pressed against the contact points when the screw is tightened. A special dowel pin helps with accuracy of fit and simultaneously makes it impossible to mount the insert incorrectly. That results in a high degree of dimensional stability and repeat accuracy. The fact that the insert contact surface is not ground when creating the cutting edge width, and the entire insert thickness is therefore maintained, also contributes to the high stability of the MX system. Special profiles outside the standard range are offered by Walter from ten pieces and are available via the Walter Xpress service within four weeks.

-

Drive systems5 years ago

Drive systems5 years agoIntelligent frequency inverters for digital production

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoThe necessity of bolted flange connection training

-

Motors8 years ago

Motors8 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors8 years ago

Motors8 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives7 years ago

Gear drives7 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control7 years ago

Motion control7 years agoWhere the robots come from?

-

Motion control7 years ago

Motion control7 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES4 years ago

POWER TRANSMISSION TECHNOLOGIES4 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoCustom hobbing tool enables 45-degree angles