Belt and Belt Drives

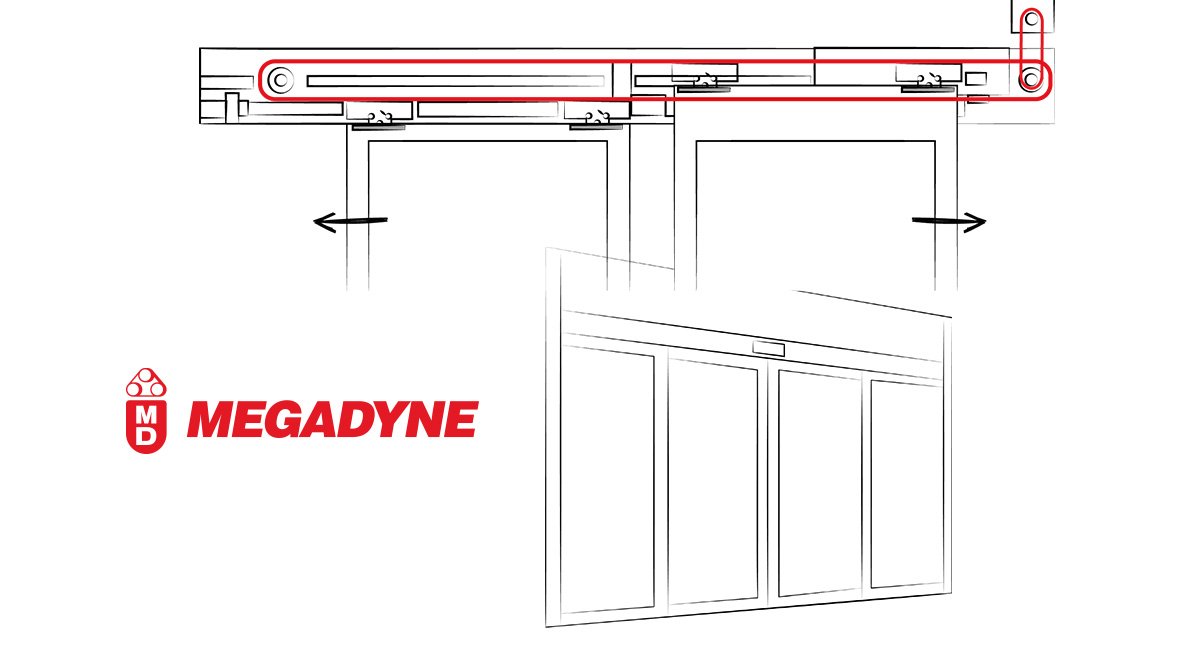

Megadyne timing belts for automated doors

Automated doors should deliver reliability and safety. They must function properly and smoothly while ensuring long hours of flawless operation even to over 5 million cycles. The doors often operate in high-traffic areas requiring them to be durable, wear-resistant, and able to withstand intensive usage. Megadyne, a leader in power transmission solutions and a member of the AMMEGA Group, provides a whole range of polyurethane and rubber open-end timing belts that help achieve these goals.

Reliable power transmission solutions for automated doors

Megadyne timing belts provide such qualities as:

– energy efficiency,

– low maintenance,

– long service life,

– and quiet operation, positively influencing customer satisfaction.

The company’s solutions exhibit high environmental tolerances, being resistant to humidity, heat, and cold. Antistatic and fire-retardant properties as per EN 45545-2 deliver top-level operational safety. Megadyne timing belts are suitable also for elevator doors opening and closing.

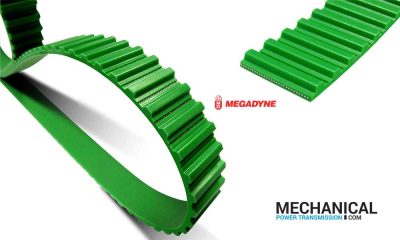

MEGALINEAR timing belts

MEGALINEAR timing belts

MEGALINEAR open-end timing belts are made from thermoplastic polyurethane, which provides power transmission systems for automated doors with superior wear and abrasion resistance. The design results in reliability and excellent dimensional stability. High-strength zinc-coated steel tension members are responsible for extremely low elongation.

Timing belts from the MEGALINEAR product family exhibit high resistance to oils, greases, hydrolysis, and ozone. They are maintenance-free. The working temperature reaches from –25 °C up to 80 °C.

‘MEGALINEAR polyurethane belts are a preferred option for automated doors in clean-room environments as their wear results in less dust or particles than in the case of rubber belts. This quality makes them the ideal fit,’ notices Andreas Lutz, Global Elevator Industry Manager at the AMMEGA Group.

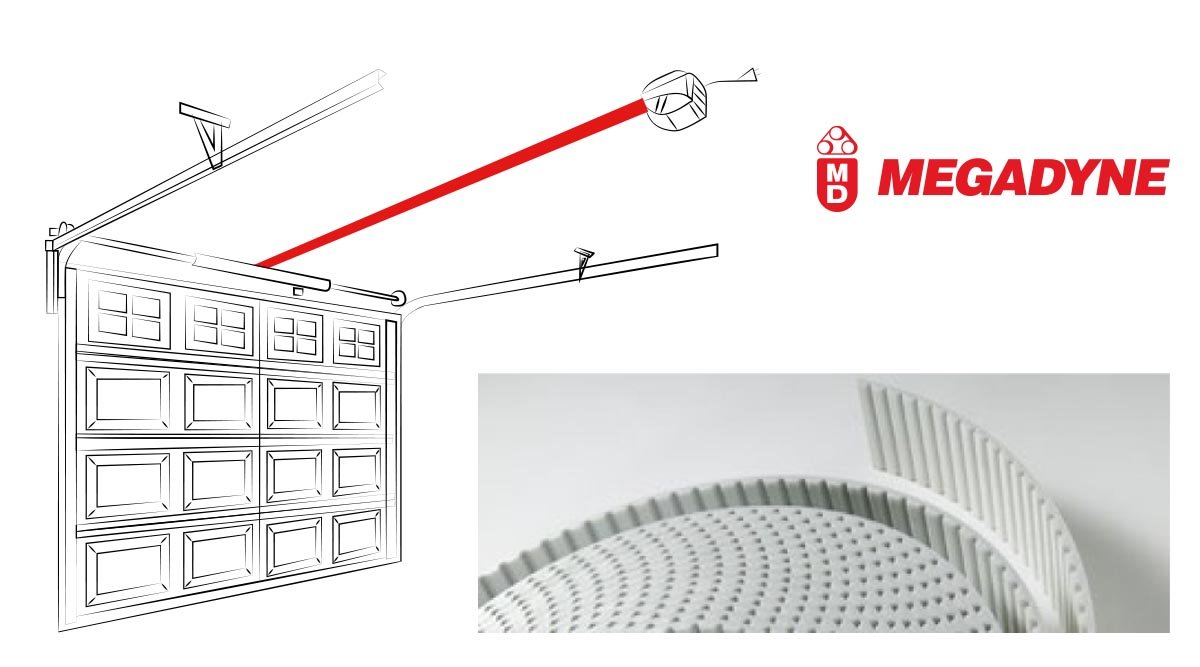

Megadyne rubber open-end timing belts

Megadyne rubber open-end timing belts endow automated door power transmission systems with quiet operation. Rubber has the quality of absorbing vibration, thus the whole mechanism operates with less noise nuisance.

The use of Megadyne rubber open-end timing belts translates into cost savings, as the belts are maintenance-free and provide a longer service lifetime. The standard working temperature reaches from –20 °C up to 80 °C. Belts are resistant to abrasion and keep a constant length. High flexibility is the result of the fibreglass cords used.

Standard Megadyne rubber open-end timing belts are manufactured with polychloroprene compound, however, other special compounds are available on request to meet specific automated door requirements. Typically used profiles include 5 or 8 pitch belts, in RPP and STD profiles.

Contact Megadyne experts

Are you looking for a perfect power transmission solution for automated doors? Contact Megadyne experts and design a system tailored to your needs.

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoThe necessity of bolted flange connection training

-

Drive systems6 years ago

Drive systems6 years agoIntelligent frequency inverters for digital production

-

Motors9 years ago

Motors9 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors9 years ago

Motors9 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives8 years ago

Gear drives8 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control8 years ago

Motion control8 years agoWhere the robots come from?

-

Motion control8 years ago

Motion control8 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES5 years ago

POWER TRANSMISSION TECHNOLOGIES5 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoCustom hobbing tool enables 45-degree angles