Belt and Belt Drives

Megalinear MegaEco Biobased – a Sustainable Belt Solution from Megadyne

Megadyne has taken yet another step towards sustainability in power transmission. Namely, Megalinear MegaEco Biobased Open End Timing Belt, which is joining the energy efficiency concept in Megadyne’s ecofriendly solutions. The MegaEco range is made with a polymer derived partially from vegetable sources and its production lowers CO2 emissions. Businesses committed to sustainable operating, carbon footprint reduction, and saving resources shall now have an opportunity to expand their pro-planet initiatives.

What’s new?

The most revolutionary idea behind Megalinear MegaEco Biobased is the use of the vegetable polymer. The technological field, in recent years, has been introduced to renewable polymers derived from vegetable oils.

Megadyne proudly stepped in to implement the new compound to power transmission applications. Moreover, after thorough testing, the results confirmed the lack of performance compromises when compared to fossil- based raw materials. Whereas the production emissions of CO2 have been reduced drastically. This revolution opens an environment-caring door for industries such as Agriculture, Energy, Pharma, Material Handling, and Robotics & Automation.

Characteristics

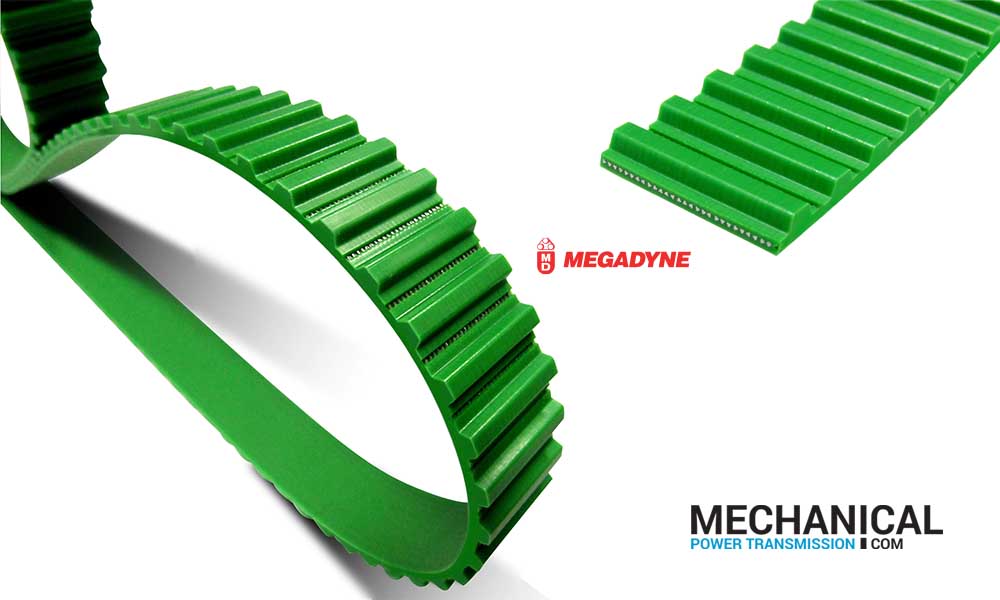

The standard compound of the Biobased Timing Belt is green thermoplastic Polyurethane. Megadyne dyed the belt to provide a contrast to identify and track any maintenance and performance issues, additionally fitting the tone of Agriculture applications such as Vertical Farming. While being an eco-friendly and impact-reducing alternative to standard belt solutions, Megalinear MegaEco Biobased doesn’t compromise the quality of

performance – the tooth strength and cord breaking load remain intact. The line is available in the most common pitches (T5/T10 AT5/AT10) making it fully interchangeable with standard belts available in the market. You can join the belts together to design a conveying solution of any length needed.

The green colour of Megalinear MegaEco Biobased makes it easier to identify and track any maintenance and performance issues. It’s also more aesthetically pleasing. The colour of the belt perfectly blends with the

greenery of the vertical farms, creating a more visually appealing environment.

Find out how Sustainable Timing Belts can enhance your business!

Megadyne high technology extrusion lines combine the Polyurethane and Vegetable Polymer compounds into a powerful and innovative Megalinear open end timing belts. The same compound is also available for Megaflex range, the Megadyne endless timing belts. It might be said that this “green” belt option supports businesses

that have made sustainability an essential part of their corporate culture and are keen on protecting the environment.

Megadyne encourages all parties interested in environmental responsibility to contact the sales representatives to fully explore Megadyne MegaEco Sustainable Belting Solutions.

-

Drive systems4 years ago

Drive systems4 years agoIntelligent frequency inverters for digital production

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoThe necessity of bolted flange connection training

-

Motors7 years ago

Motors7 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors7 years ago

Motors7 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives6 years ago

Gear drives6 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors7 years ago

Motors7 years agoGet a first-class ticket to productivity

-

Motion control6 years ago

Motion control6 years agoWhere the robots come from?

-

Motion control6 years ago

Motion control6 years agoRexnord to Acquire Centa Power Transmission

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoCustom hobbing tool enables 45-degree angles

-

POWER TRANSMISSION TECHNOLOGIES3 years ago

POWER TRANSMISSION TECHNOLOGIES3 years agoEUROTRANS Board meets for its first session in 2021