Drive systems

Management statement: Nord drive system heralds a new era of drive technology

With its latest product developments from the high-efficiency portfolio, Nord drive system once again demonstrates its competence and innovative strength in mechanical and electronic drive technology. This is what the managing partners Jutta Humbert and Ullrich Küchenmeister say.

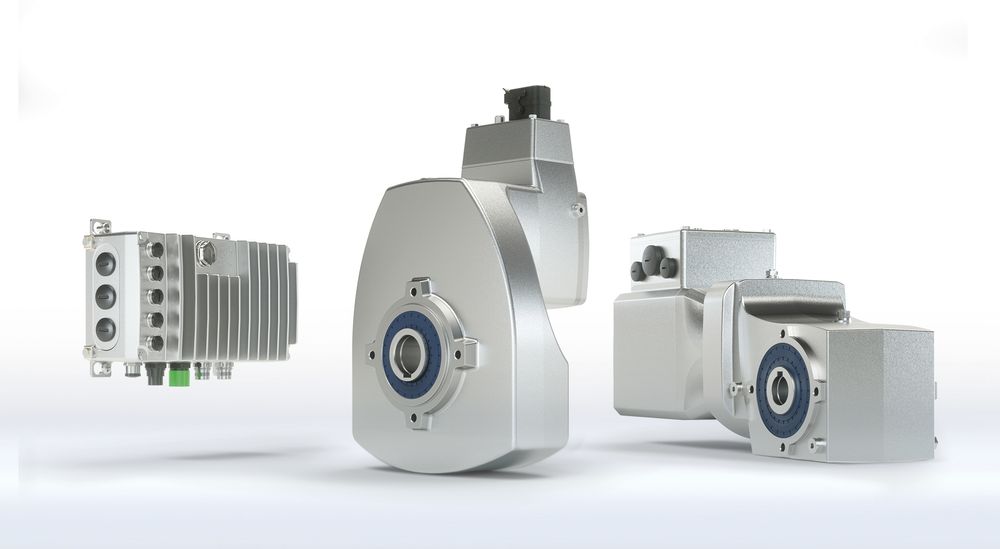

“We focus on becoming better and better, and developing innovative drive solutions for more than 100 branches of industry. It takes courage to break new ground and to challenge the status quo. We have the courage because we are listening to our customers’ needs and wants, and transform them into sustainable products and concepts. With 48 companies in 36 countries worldwide, we are close to our customers. We on the management board and each of our more than 4,000 employees worldwide are very proud of our truly revolutionary duo drive geared motor. This heralds a new era of drive technology! The patented new duo drive geared motor has an efficiency of up to 92% and is thus one of the most efficient geared motors in its power class. This was achieved by integrating our IE5+ synchronous motor into a single-stage helical gear unit – a completely new approach in geared motor design. With our IE5+ synchronous motor, we have already been able to significantly reduce losses compared to the current IE4 series. duo drive goes one step further and sets new standards with regard to power density, installation space and version reduction. Our new high-efficiency portfolio is supplemented by the decentralised nordac on frequency inverter. With its integrated ethernet interface and its very compact design, it provides a highly economic plug-and-play solution for Iot environments. For more than 55 years, we have been meeting highest quality standards with our expertise, experience and high depth of production. All quality-determining components are produced in our own factories and we are currently operating eight production locations with cutting-edge technology. In our technology centre near Hamburg, we are developing the future of drive technology – worldwide.”

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoThe necessity of bolted flange connection training

-

Drive systems6 years ago

Drive systems6 years agoIntelligent frequency inverters for digital production

-

Motors9 years ago

Motors9 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors9 years ago

Motors9 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives8 years ago

Gear drives8 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control8 years ago

Motion control8 years agoWhere the robots come from?

-

Motion control8 years ago

Motion control8 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES5 years ago

POWER TRANSMISSION TECHNOLOGIES5 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoCustom hobbing tool enables 45-degree angles