Motors

Low voltage Dc Servo Motors that redefine performance expectations

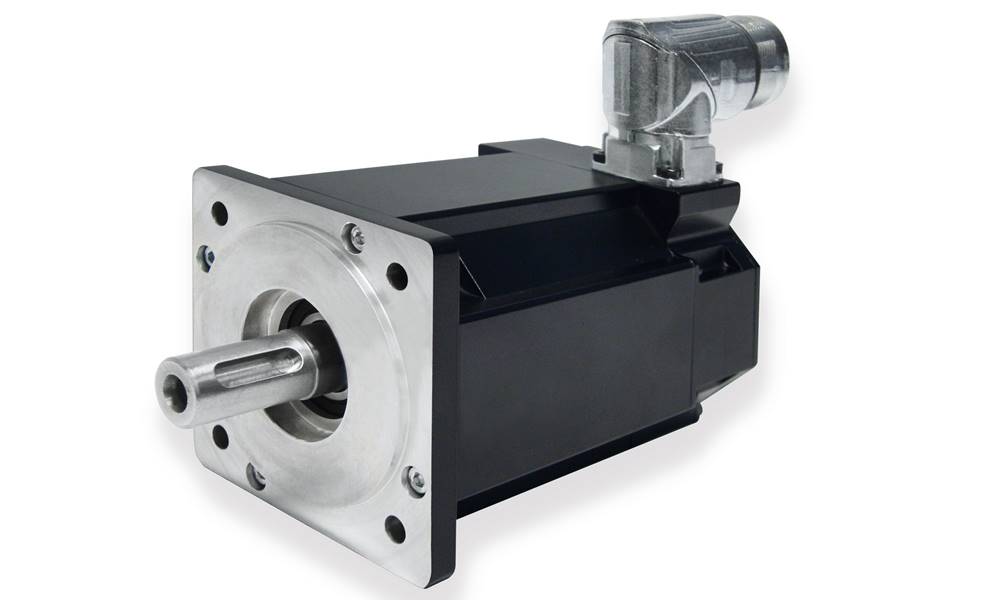

Precision motor specialists INMOCO is launching the first of a series of low voltage DC servo motors to meet the need of new and emerging applications in robotics, automated guided vehicles (AGV), medical equipment and other fields.

Made in the US as an extension to Kollmorgen’s AKM2G portfolio of servo motors the new low voltage range includes 24Vdc, 48Vdc, 72Vdc and 96Vdc units as standard, with options to go up to 105Vdc.

The first motor available form INMOCO is the AKM2G Size 3, Connector version, which includes M23 SpeedTec (dual) and htec (hybrid) connectors as standard options. There is a choice of feedback options, including absolute encoder, commcoder or resolver.

Expected during fourth quarter of 2019, further options will be available, including Size 3 flying lead versions and Size 2, Size 4 with both flying leads and connectors.

With windings specially designed for low voltage applications, the new AKM2G motors have been designed for high power and torque density, thus offering more optimised motion performance.

The AKM2G series represents the latest generation of synchronous servo motors and are available in powers from 0.3kW to10 kW. They are designed to provide continuous torque up to 30% greater than earlier servos and support a wide range of feedback, brake, thermal sensor and seal options.

The greater power output offered by the AKM2G motor means OEMs can design compact high performance machines, while end-users can upgrade existing machinery to increase speed and/or throughput.

Established in 1987, INMOCO now offers an extensive range of motion control equipment including: compact servo amplifiers, position controllers, stepper motors, PLC controllers, linear motors, sensors, electric actuators and gearheads. INMOCO’s product portfolio is supported by extensive applications and technical expertise, in addition to customer-specified electro-mechanical development and sub-assembly services; including calibrating and testing in a class 10,000 clean room facility.

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoThe necessity of bolted flange connection training

-

Drive systems6 years ago

Drive systems6 years agoIntelligent frequency inverters for digital production

-

Motors9 years ago

Motors9 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors9 years ago

Motors9 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives8 years ago

Gear drives8 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control8 years ago

Motion control8 years agoWhere the robots come from?

-

Motion control8 years ago

Motion control8 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES5 years ago

POWER TRANSMISSION TECHNOLOGIES5 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoCustom hobbing tool enables 45-degree angles