Industrial Hardware and Machine Parts

Hexagon presents complete solution for laser scanning on the machine tool

New on-machine tool laser scanning measurement solution enhances productivity and data capture.

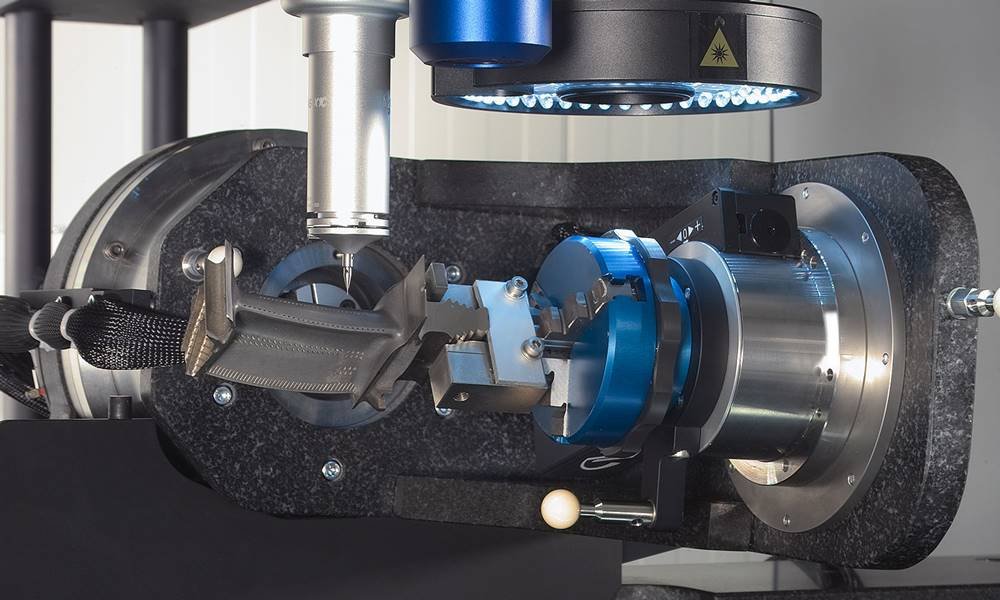

Hexagon’s Manufacturing Intelligence division is bringing laser scanning with metrology levels of precision to machine tool measurement with its new LS-C-5.8 system.

Ideal for measuring freeform or large surfaces, the LS-C-5.8 integrates with machine tools to create point cloud images of a part’s entire surface. Dedicated software presents the data in an easy-to-understand format, making it simple to quickly identify fluctuations in quality and correctly align a part for reworking while it is still clamped to the machine tool.

Andreas Hieble, Product Manager Metrology Solutions for Hexagon’s machine tool measurement product line says: “We’ve drawn on our expertise in developing market-leading laser scanners for coordinate measuring machines and portable measuring arms to meet manufacturers’ growing demand for a new, productivity-enhancing approach to machine tool measurement. Today, users typically have to create and analyse many single points when measuring with a machine tool. The LS-C-5.8 laser scanner solution transforms the process by automatically capturing thousands of points per second and rapidly delivering rich data in an easy-to-read form.”

The LS-C-5.8 is a fixed blue line sensor that delivers precise results whether measuring shiny or very dark surfaces across a huge variety of applications and surface types. It combines a compact design with a large field-of-view so that it can be used to create point clouds on small machines and in environments where part accessibility is limited. And its software enables the comparison of the real-life part with designs in the CAD model.

The LS-C-5.8’s software is compatible with controls from Siemens, Fanuc and Heidenhain. It is designed to marry high performance with ease-of-use and its features include the display of colour-mapped point clouds. It is able to use data to align the part on the machine (Best-Fit) and can export files in an STL format. As a result, the data it captures can be ready in real time on the shop floor, enabling manufacturers to quickly identify and address production issues.

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoThe necessity of bolted flange connection training

-

Drive systems6 years ago

Drive systems6 years agoIntelligent frequency inverters for digital production

-

Motors9 years ago

Motors9 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors9 years ago

Motors9 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives8 years ago

Gear drives8 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control8 years ago

Motion control8 years agoWhere the robots come from?

-

Motion control8 years ago

Motion control8 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES5 years ago

POWER TRANSMISSION TECHNOLOGIES5 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoCustom hobbing tool enables 45-degree angles