Controls

Effective process optimisation in the production of LDPE

Quality control has always been important to us. But we were not really aware at the beginning that we could also ensure a considerable process optimisation by means of the OP5. At first, the measuring device delivered results that seemed irreal to us. This was solely due to the fact that even several daily laboratory measurements could not adequately reflect the dynamic changes in production. These variations only became visible through the short measuring interval of the automated OP5 online measurement. The continuous quality control with the use of the OP5 allows us to optimise the production process at any time and at the same time to finally classify our batch material. The advantages such as the fully automated measurement, the considerable time savings through the reduction of transition times and the high reproducibility through the OCS equipment, in comparison to the manual ISO1133 measurement, contribute to an effective process optimisation and reduction.

-

Drive systems4 years ago

Drive systems4 years agoIntelligent frequency inverters for digital production

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoThe necessity of bolted flange connection training

-

Motors7 years ago

Motors7 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors7 years ago

Motors7 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives6 years ago

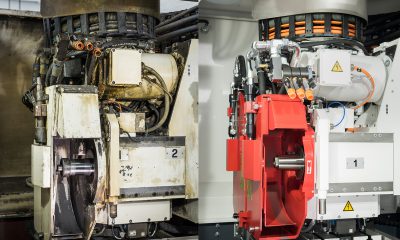

Gear drives6 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors7 years ago

Motors7 years agoGet a first-class ticket to productivity

-

Motion control6 years ago

Motion control6 years agoWhere the robots come from?

-

Motion control6 years ago

Motion control6 years agoRexnord to Acquire Centa Power Transmission

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoCustom hobbing tool enables 45-degree angles

-

POWER TRANSMISSION TECHNOLOGIES3 years ago

POWER TRANSMISSION TECHNOLOGIES3 years agoEUROTRANS Board meets for its first session in 2021