Motion control

Direct drive absolute value unit

Machinery in a variety of industrial sectors has benefited from the properties, safety standards, compactness and precision of the positioning units driven by KOLLMORGEN linear motors.

Today, the well-known Mondial linear motor modules, long-established on the market, are more efficient and have higher quality standards, smaller dimensions, and an excellent price-quality ratio thanks to the compactness and safety of KOLLMORGEN products.

Mondial Spa is one of the foremost companies in the power transmission sector. For more than half a century, it has represented leading foreign companies, designing and producing a wide range of specialist products which can meet the most varied demands of many different industrial sectors. It is a parent company of the group of businesses specializing in the design and manufacture of specialist bearings for a number of different industrial applications. Boasting a design department, unusual feature for a distribution company, the Mondial Group works very closely with its clients to meet their needs, optimizing costs and benefits.

Mondial needed to update and expand its range of modules driven by linear motors and upgrade the product design and performance in order to be able to offer customers a new and improved range of components in line with trends in the market as well as its own quality standards. The improved performance of the product has to be allied with the affordability of the proposed solutions; this was to be the key to success.

The Milan-based company began their search for a well-known partner in the market with which to operate in partnership. A meeting with KOLLMORGEN confirmed their interest in collaborating with a leading company capable of producing complete solutions. The result was a winning combination: both players immediately saw opportunities to increase their presence and competitive strength in the Italian market where the first applications combining the Mondial linear units with KOLLMORGEN linear motors were introduced at the start of 2017.

“The start of this partnership has been very exciting for us” explained Angelo Trombetta, Direct Drives and Mechanical Transmission Manager for Kollmorgen Italia, who has been with the project from the outset. “We have worked well with the Mondial team, mutual sharing has been useful and rewarding for all: this project has been a start, we want to tackle new challenges, continuing to provide the added value which is our hallmark”.

Complete linear movements with a high level of performance

Mondial uses KOLLMORGEN motors is its linear movement systems, which make up one of the most extensive ranges of direct drive linear modules on the Italian market. The benefits of direct drives are clear: very high performance, OEE (overall equipment efficiency) performance, no deterioration in performance over time, providing a transmission with maximum efficiency. The direct drive of a linear motor under load also means that mechanical transmission components, recirculating ball screws, gears, belts, and other components can be done away with, eliminating mechanical play, increasing rigidity and therefore productivity.

The linear units produced can be used in a wide range of machinery in applications such as printing, packaging, presses, plastic deformation, machine tools, handling, laser cutting, measurement, inspection, milling, assembly, textiles, simulators, and many more.

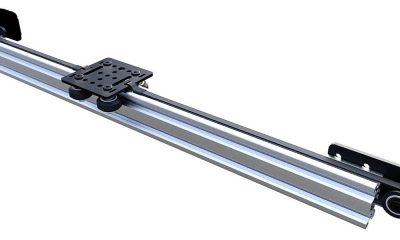

Transport and positioning unit MLM7 N

High levels of dynamic performance, considerable load capacity, and precision are the distinguishing features of the new MLM7 N series from Mondial. It is a complete feed and positioning unit, vital for linear movement in precision applications. The base component is made from high-strength extruded aluminium, which can be used as a free-standing element, the profile of which has been designed to suit different types of linear motors. It also provides high translation forces, whilst always ensuring fluidity of movement. The delivery programme, updated by Mondial, is structured in order to satisfy any application requirements in terms of speed, precision of positioning, load capacity, etc.

With regard to protection systems, the basic version has been designed with uncovered guide rails and protected recirculating ball slides with standard friction seals. The version with a linear motor has a stainless-steel plate to cover the motor. If the application requires, the MLM7 module can also be fitted with a PVC protective bellows. On request, Mondial can design and produce special protection systems to suit specific safety requirements or working environments. Maintenance is reduced to a minimum with this new range: the different versions incorporate a grease distribution system for all the moving components; the version with a linear motor uses lubricators integrated into the recirculating ball slides. The Mondial linear motor systems can also be fitted with inductive, magnetic, and optic linear encoders.

A direct drive linear motor is, in fact, a rotary engine laid flat and driven directly under load.

With no mechanical transmission components, the design offers an exceptional level of performance, very high rigidity, dynamic speed, and acceleration, a high level of positioning precision, compact dimensions, low cogging, maintenance-free running, and quiet operation as well as a high degree of precision.

Advantages of the ICH linear motors

- Maintenance free, increased precision and bandwidth

- Uniform speed profile and reduced noise

- Transmission of forces without mechanical components such as couplings, toothed belts, etc.

- No gear reducers, screws, or lubrication

- Increased reliability of the application

- Vast selection of motor sizes with differing power ranges for universal use in all linear drives

- Increase in performance of the entire system

- Compact drive solution with reduced height

- Simple and more compact design of the machine

- Increased bandwidth and response speed compared with ball screw or gear-wheel drives.

- Reduced noise, fewer components and lower overall operating costs

-

Drive systems4 years ago

Drive systems4 years agoIntelligent frequency inverters for digital production

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoThe necessity of bolted flange connection training

-

Motors7 years ago

Motors7 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors7 years ago

Motors7 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives6 years ago

Gear drives6 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors7 years ago

Motors7 years agoGet a first-class ticket to productivity

-

Motion control6 years ago

Motion control6 years agoWhere the robots come from?

-

Motion control6 years ago

Motion control6 years agoRexnord to Acquire Centa Power Transmission

-

Industrial Hardware and Machine Parts7 years ago

Industrial Hardware and Machine Parts7 years agoCustom hobbing tool enables 45-degree angles

-

POWER TRANSMISSION TECHNOLOGIES3 years ago

POWER TRANSMISSION TECHNOLOGIES3 years agoEUROTRANS Board meets for its first session in 2021