Drive systems

Drives for pallet conveyor technology

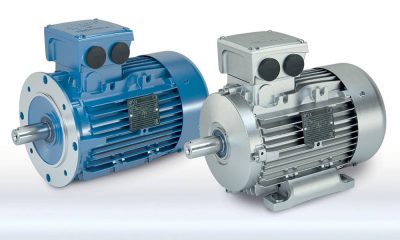

Pallet conveyor technology primarily requires economical drive solutions with high overload capacity. NORD DRIVESYSTEMS supplies optimally matched, individually configurable and flexible drive technology which reduces the number of versions and minimises costs, especially for transporting pallets and cage pallets with roller or chain conveyors.

For simple pallet conveyor technology applications, NORD has developed an efficient drive combination consisting of an asynchronous motor and a NORDAC BASE frequency inverter. This drive solution is specially tailored to the requirements of pallet conveyor technology and provides dependable technology with a robust design. It can be combined with all NORD geared motors and can be flexibly extended according to requirements, or the customer’s specifications. Standardisation results in a reduction of the number of versions. This considerably reduces stocks of spare parts, optimises maintenance and saves costs in the sense of TCO (Total Cost of Ownership).

The three-phase asynchronous motors provide powers up to 1.5 kW and feature high overload capacity, solid workmanship and a long service life. The frequency inverters are installed close to the motor and are equipped with an integrated PLC. The freely programmable PLC processes the data from sensors and actuators, provides diagnostic options and communicates with the higher level controller. A pre-installed software for control, parameterisation and diagnosis is configured for the special drive requirements of pallet conveyor technology.

The drive units can be integrated into all common bus systems. The AS interface or I/O interface are especially suitable as a simple and cost oriented solution for communication in pallet conveyor technology. A different bus system can be used without any problems if there are more sophisticated requirements.

Dependable, flexible, robust and service and maintenance friendly – with the combination of an asynchronous motor and the NORDAC BASE, NORD has created an application oriented drive solution for pallet conveyor technology.

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoThe necessity of bolted flange connection training

-

Drive systems6 years ago

Drive systems6 years agoIntelligent frequency inverters for digital production

-

Motors9 years ago

Motors9 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors9 years ago

Motors9 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives8 years ago

Gear drives8 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control8 years ago

Motion control8 years agoWhere the robots come from?

-

Motion control8 years ago

Motion control8 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES5 years ago

POWER TRANSMISSION TECHNOLOGIES5 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoCustom hobbing tool enables 45-degree angles