Gear Manufacturing Services

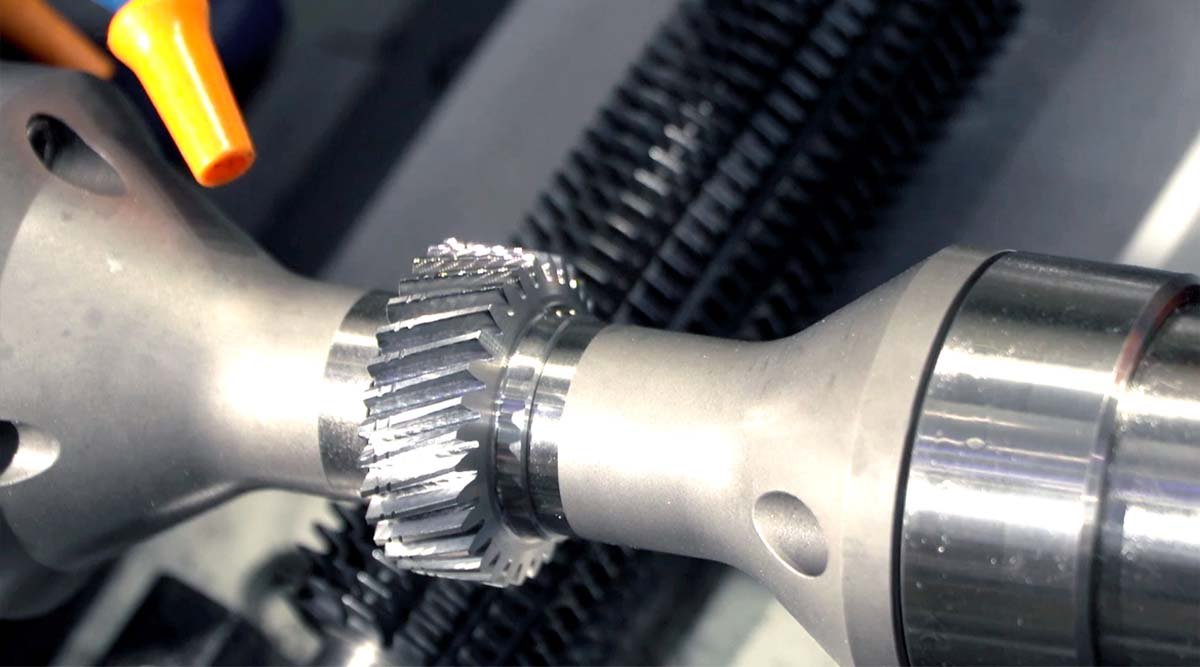

Planetary gear hobbing with EMAG KOEPFER K 16

In the world of machine tools, the optimal design of processes is crucial to achieving the highest precision and efficiency. In today’s blog article, we spoke to Jörg Lohmann, Head of Technology and Product Management and Member of the Management Board at EMAG KOEPFER, to find out more about how hobbing processes are designed, using planetary gears as an example. Jörg Lohmann brings almost 20 years of experience in the design and application of gear hobbing machines and gear cutting processes and gives us a deeper insight into the decision-making behind these processes.

Mr. Lohmann, in your opinion, what makes EMAG KOEPFER special?

That’s not so easy to answer. EMAG KOEPFER is a very informal company where everyone basically knows each other. This combination of collegial cooperation, professional competence and experience contributes to the fact that I still enjoy going to work after all these years. I think our customers feel that, too. They receive individual and competent advisory services and support for every project and can rely on their concerns being taken seriously. Thanks to our connection to the EMAG Group, we can also react very individually to customer requests, for example, to implement complex manufacturing processes – right through to turnkey manufacturing systems. EMAG KOEPFER, therefore, offers a unique blend of personal contact, expertise and a wealth of experience – all of which make the company and our solutions something very special.

EMAG KOEPFER K 16

Experience is also important for the topic we are discussing today, the design of hobbing processes. How exactly do you proceed here?

Yes, experience is essential, but first you have to fully understand and penetrate the physical and technical aspects of this complex technology. This requires a profound mathematical understanding, supplemented by general know-how in the field of machining processes. If this is the case here at EMAG KOEPFER, I would go even further and say that experience is the most important resource in the development of gear cutting processes. But now I’m getting ahead of myself. In order to be able to describe the whole development process a little more vividly, I would like to explain it using an example. I was thinking of a planetary gears. Here, high demands are placed on the end product, which also has to be manufactured in large quantities.

The design usually begins with the receipt of the workpiece drawing and the specification sheet from the customer, which contains the framework conditions, such as the requirements for upstream and downstream processes, the quality class after gear machining, the desired quantities, etc. This information forms the basis for the initial design as well as forms the basis for the first drafts of a machining process. There are a large number of factors that need to be taken into account, as well as countless possibilities for process design. And, this is precisely where our experience comes into play, as we can rule out many less effective processes at a very early stage. Based on this, you then enter into a variant calculation and compare different process variants in order to determine the most economical solution.

What is the first question you ask yourself?

First of all, you need to know what the finished component should look like. The entire process chain and the requirements placed on gear machining are then derived from this. Other aspects then come into consideration, such as whether we use wet or dry machining. Dry machining is usually more efficient, especially for large quantities. Higher cutting data can be achieved and operations such as washing before hardening can be saved. In this way, the handling of the workpieces and lead times can be reduced. The dry process, therefore, offers many advantages, but also places high demands. On the one hand, you need the right machine with the necessary performance and precision and, on the other, you need a certain number of pieces to be able to run the process perfectly. This is where experience comes into play again, which is simply necessary to perfect this process. Fortunately, we at EMAG KOEPFER meet all these requirements – of course also for our example workpiece “planetary gears,” for which we have already supplied countless machines all over the world.

What about tools? What needs to be considered here?

In addition to the machine, the design of the hob cutter is of course the decisive criterion in the hobbing process, i.e. the design of the hob cutter and the selected cutting data, as these influence each other. The following questions arise. What kind of material should the hob cutter be made of? Should you choose a shank hob or a bore hob? The number of threads of the milling cutter and so on. All of this in turn influences the possible cutting data and also the quality of the tooth profiles produced. This actually takes us deep into the design of the hobbing process, because every decision that is made here also has an impact on the costs in the end. A shank hob is more expensive than a bore hob, but it can be designed to be longer and can, therefore, machine more components before it has to be reground. The machining time and the quality of the tooth profiles produced depend on the cutting data and design of the hob cutter. As I said, basically everything here depends on each other and there is no getting around trying it out.

How can you imagine this trial and error?

Well, of course we don’t try out the different designs in reality, but use simulation software for this process step. But here again I have to refer to experience, because we can look back on many years of process design and of course already know which values make sense to start with. Everything that comes after that is basically the search for the optimum cost/quality ratio. In other words, we look for the machining process in which we can produce the required quantities in the desired quality at the lowest unit production costs. This is then the optimum machining process. In our example, this means that we can machine planetary gears in less than nine seconds, at least as far as soft machining is concerne. The planetary gears are first pre-milled and then hardened and must then be hard-fine machined. But going into this in more detail would go beyond the scope of this interview. I would, therefore, like to take this opportunity to refer you to our webinar, in which I explain the entire process in detail.

Jörg Lohmann, Head of Technology and Product Management and Member of the Management Board at EMAG KOEPFER

Here you will find the webinar mentioned by Mr. Lohmann with further comprehensive information about the gear hobbing process.

Mr. Lohmann, thank you for the interview.

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoThe necessity of bolted flange connection training

-

Drive systems6 years ago

Drive systems6 years agoIntelligent frequency inverters for digital production

-

Motors9 years ago

Motors9 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors9 years ago

Motors9 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives8 years ago

Gear drives8 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control8 years ago

Motion control8 years agoWhere the robots come from?

-

Motion control8 years ago

Motion control8 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES5 years ago

POWER TRANSMISSION TECHNOLOGIES5 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoCustom hobbing tool enables 45-degree angles