Industrial Hardware and Machine Parts

New OCM and grinding functions for the TNC

HEIDENHAIN introduced two new TNC functions that open up completely new possibilities for shop-friendly machining with high process reliability. Thanks to OCM, the user can program innovative milling strategies for any pocket and island directly on the TNC control. The OCM algorithm uses ideas taken from trochoidal milling but considerably expands their range of application. Meanwhile, new grinding functions round off the TNC 640’s capabilities for complete machining in a single setup.

Optimized Contour Milling (OCM): the next generation of trochoidal milling

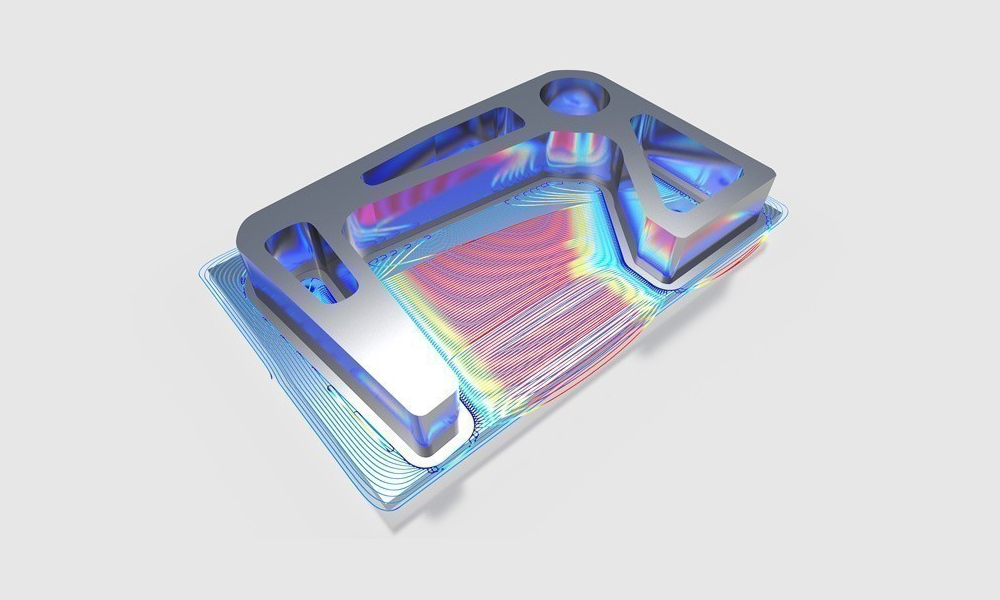

Trochoidal milling stands for highly dynamic milling at excellent material removal rates. Unfortunately, the tool paths involved are optimal only for grooves. At EMO 2019, HEIDENHAIN changed this state of affairs with a new option for the TNC 640, TNC 620, and TNC 320 controls. Optimized Contour Milling (OCM) allows the trochoidal milling principle to be utilized for a considerably wider range of applications. In addition to the roughing of any open or closed pocket and island, OCM also offers cycles for the finishing of pocket floors and side walls.

As is the case with trochoidal milling, OCM limits the wrap angle and permits milling along the entire cutting edge. With OCM, the user can program any contour on the TNC 640 as usual from the shop floor. The control then automatically calculates the optimum tool paths for holding the cutting parameters constant. The subsequent machining operation runs with continuously optimum cutting values, resulting in increased machining speed and a noticeable reduction in tool wear.

A sample part presented at EMO showed just how effective the new milling strategy is. For our sample workpiece at the tradeshow, OCM lowered the machining time and tool wear by a factor of three compared with conventional milling strategies.

Grinding: achieve perfect finishes in a single setup

The TNC 640 was already able to handle milling and turning operations in a single setup. But at EMO, HEIDENHAIN showed that the control can master a third production process for the complete machining of a workpiece; namely, jig grinding. Having a milling, turning, and grinding package on a single machine offers many benefits, particularly for quality-intensive industries such as mold making and medical technology. These industries can now machine parts to exceptional surface quality in a single clamping.

The new functions enable the jig grinding of any contour on a milling machine. In addition, easy-to-use standard dressing cycles on the TNC 640 can true up grinding tools inside the machine tool. The standardized operating design for milling, turning, and grinding makes usage particularly easy. What’s more, optimized tool management for every process supports the user with both grinding and dressing.

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoThe necessity of bolted flange connection training

-

Drive systems6 years ago

Drive systems6 years agoIntelligent frequency inverters for digital production

-

Motors9 years ago

Motors9 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors9 years ago

Motors9 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives8 years ago

Gear drives8 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control8 years ago

Motion control8 years agoWhere the robots come from?

-

Motion control8 years ago

Motion control8 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES5 years ago

POWER TRANSMISSION TECHNOLOGIES5 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoCustom hobbing tool enables 45-degree angles