Events

Interroll establishes new service organization

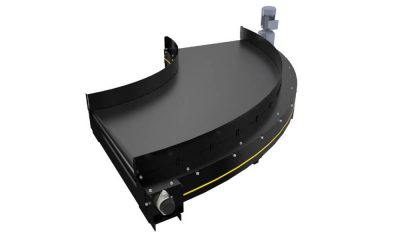

Sant’Antonino, Switzerland. June 1, 2021. Interroll is expanding its range of services to continuously improve convenience for system integrators and end users. To this end, Interroll is placing its services for new and existing customers, marketed under the name “Interroll Lifetime Service”, on a new organizational footing. The company has therefore created a central service unit in Sinsheim, Germany, which is responsible for European spare parts and repair management, maintenance, installation services and training measures.

A central element of the new organization is the newly created central warehouse for standard spare parts in Ketsch near Heidelberg, which is operated by an efficient logistics partner. This is where over 90 percent of the operation-critical spare parts for key products and conveyor modules for material flow solutions based on Interroll’s modular platform solutions are kept. Its central location in Europe, direct connection to the major long-distance transport axes and proximity to Frankfurt Airport ensure a rapid supply of spare parts to European customers and users. Depending on the respective service contract, delivery of corresponding orders is guaranteed within 24 hours. This also applies to the repair and general overhaul of products such as drum motors, special conveyor modules and key Smart Pallet Mover (SPM) products for which the central workshop in Baal near Düsseldorf and its decentralized repair facilities in the various European countries are responsible.

The new service organization, called “Global Lifetime Service”, includes around 100 qualified Interroll service employees in the European subsidiaries as well as certified partners who are responsible for providing customer-oriented support and carrying out the respective maintenance, repair and installation services throughout Europe within the framework of the central service unit in Sinsheim, the central warehouse in Ketsch and the repair facilities.

“Customer satisfaction is our top priority, so it is only logical to expand our services. With the reorganization of our service organization for system integrators, we are not only significantly increasing the efficiency and performance of our customer service. In addition, we are creating the basis for being able to develop and offer future innovations in the service business even faster,” explains Jens Strüwing, Executive Vice President Products & Technology of the Interroll Group.

The new service organization, which is set up as a profit center, will support new and existing customers with a variety of needs-based spare parts services In addition, installation and maintenance services— such as on-site commissioning, maintenance, inspection, repair and optimization of existing solutions based on Interroll technologies—will be offered. Moreover, online support for preventive maintenance measures and training services will be provided. Following its introduction in Europe, a corresponding reorganization for the marketing of Interroll Lifetime Service will also take place in America and Asia.

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoThe necessity of bolted flange connection training

-

Drive systems6 years ago

Drive systems6 years agoIntelligent frequency inverters for digital production

-

Motors9 years ago

Motors9 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors9 years ago

Motors9 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives8 years ago

Gear drives8 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control8 years ago

Motion control8 years agoWhere the robots come from?

-

Motion control8 years ago

Motion control8 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES5 years ago

POWER TRANSMISSION TECHNOLOGIES5 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoCustom hobbing tool enables 45-degree angles