Genel

In Forlì, the first Bonfiglioli Group ISO 50001- certified plant

The ISO 50001:2018 certification “Energy management systems” represents the international standard that specifies the requirements for creating, implementing, maintaining and improving an Energy Management System, helping organizations in the process of integrating energy efficiency into all business activities, including production processes.

In 2021, the Bonfiglioli Group made the strategic choice to start the certification process for the ISO 50001 Standard, starting from the Italian plant characterized by the greatest production complexity, namely that of Forlì, in the wake of the successful experience of the ISO Certifications 9001 (Quality), 14001 (Environment) and 45001 (Occupational Health and Safety) standards of its plants in Italy and abroad.

This choice fully reflects the Group’s key principles and values, with particular reference to the issues of social, environmental and energy sustainability, oriented to the entire product life cycle, from the phases of design and selection/purchase of materials and suppliers to end-of-life management and the design and construction of sustainable workplaces, also considering the other actors involved in the production chain.

The main activities that have allowed the Bonfiglioli Group to achieve this important goal are:

- Review of the Group’s Quality, Health, Safety, Environment and Energy Policy, valid for all plants in Italy and abroad, with the inclusion of specific commitments relating to energy efficiency and, more generally, sustainability;

- Creation of a dedicated team: the Energy Team;

- Energy Analysis of the Forlì plant, mapping of consumption, definition of performance indicators and energy objectives;

- Definition of procedures and documentary tools dedicated to the improved management of energy performance and the maximum integration of energy issues into business processes;

- Programming and delivery of training activities for personnel

Bonfiglioli’s commitment to supporting sustainability is constant, and the certification obtained represents a further tangible sign of its contribution to a greener world!

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoThe necessity of bolted flange connection training

-

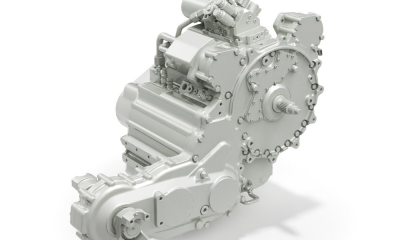

Drive systems6 years ago

Drive systems6 years agoIntelligent frequency inverters for digital production

-

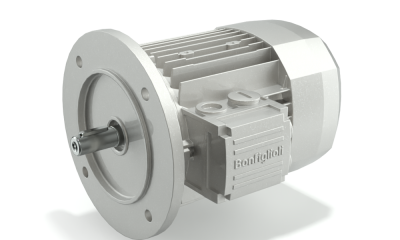

Motors9 years ago

Motors9 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors9 years ago

Motors9 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives8 years ago

Gear drives8 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control8 years ago

Motion control8 years agoWhere the robots come from?

-

Motion control8 years ago

Motion control8 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES5 years ago

POWER TRANSMISSION TECHNOLOGIES5 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoCustom hobbing tool enables 45-degree angles