Machinery manufacturing

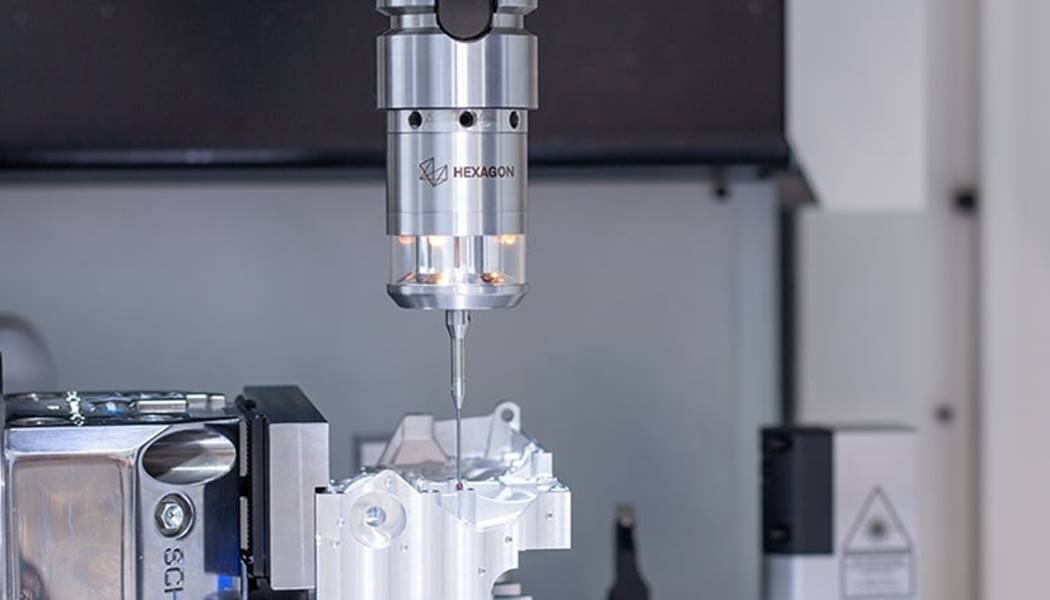

Hexagon innovates inspection of fragile parts with low force, infrared machine tool probe

New compact probe with low trigger force and high precision makes it possible to measure fragile applications and inspect small areas directly on the machine tool.

Hexagon’s Manufacturing Intelligence division has launched a new probe, the IRP40.42, which transforms the inspection of very fragile materials and small or thin-walled parts, directly on the machine tool.

The new IRP40.42 is an innovation in probe technology that meets the specific demands of manufacturers of small, fragile parts. Regular touch probes can exert too much pressure when measuring fragile parts on the machine tool, leading to damage. In addition, regular styli balls are typically too large to inspect inside the very small parts produced, for example, by the watch-making or dental industries. At the same time, manufacturers want to benefit from the productivity gains of accurately inspecting fragile parts, directly on the machine tool.

Hexagon has designed the IRP40.42 to overcome the challenges facing manufacturers across sectors that range from medical appliances through to automotive. In addition to applying a force as low as 0.08 N in the X- or Y-direction, which compares to between 0.3 N and 1,4 N for standard machine probes, the IRP40.42 can be equipped with styli balls as small as 0.2 mm in diameter.

The IRP40.42 builds on Hexagon’s highly successful touch trigger probe technology, developed for taking highly accurate measurements on coordinate measuring machines. A robust, compact housing protects the IRP40.42 from the harsh machine tooling environment, while Hexagon’s proven HDR+ infrared transmission technology ensures communication between probe and receiver.

Crucially, the IRP40.42 is extremely precise and can capture measurement points with a repeatability of 2 Sigma 1 μm while consuming extremely little energy, resulting in a battery lifetime of up to 800 hours in continuous use.

Fabio Marino, Product Manager at Hexagon, says: “We were receiving more and more enquires about a probe for taking delicate measurements in limited space. With the IRP40.42, we can now offer a solution to our customers that fits perfectly into our range of machine tool probes while matching the needs of very specific applications.”

The IRP40.42 communicates with the existing infrared receivers IRR91.42 and IRR91.50, which also work with additional Hexagon tool setters inside the machine tool. The probe is also compatible with Hexagon’s market-leading measurement software solutions.

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoThe necessity of bolted flange connection training

-

Drive systems6 years ago

Drive systems6 years agoIntelligent frequency inverters for digital production

-

Motors9 years ago

Motors9 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors9 years ago

Motors9 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives8 years ago

Gear drives8 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control8 years ago

Motion control8 years agoWhere the robots come from?

-

Motion control8 years ago

Motion control8 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES5 years ago

POWER TRANSMISSION TECHNOLOGIES5 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoCustom hobbing tool enables 45-degree angles