Belt and Belt Drives

FLEXCO ELEVATE™ transforming belt conveyor efficiency digitally

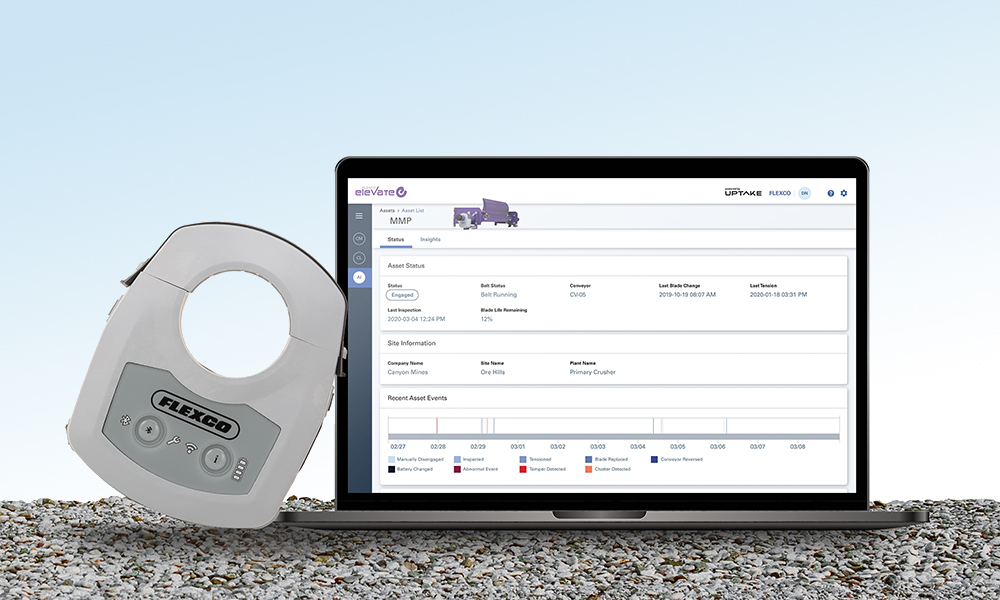

Introducing Flexco Elevate™ Belt Conveyor Intelligence™, an innovative, real-time monitoring system that harnesses the power of predictive analytics so mining, aggregate, and cement operations can remotely gather critical insights that optimize belt conveyor productivity and heighten operational efficiencies.

Flexco Elevate is a wireless platform that transfers data insights to an intuitive cloud-based dashboard via edge technology, allowing remote monitoring of belt cleaners. With intelligence that grows over time, this easy-to-use platform is designed to simplify and accelerate belt maintenance using its powerful, data-driven engine.

“Flexco has a 110-year history of innovation, working alongside our customers to deliver solutions that are in alignment with their operational goals,” said Chip Winiarski, Vice President of Marketing at Flexco. “We are proud to introduce Flexco Elevate. It’s the first technology solution of its kind and will quickly bring increased efficiencies and improved productivity to our customers’ operations.”

Flexco Elevate™ Platform Overview

Flexco Elevate, created in partnership with Uptake, an industrial AI and IoT data science leader, reduces the need for on-site inspections and allows operations to access real-time insights remotely from an intuitive dashboard, so users are able to quickly address belt conveyor performance issues and minimize unexpected downtime. The insights pipeline begins by installing a state-of-the-art Flexco Elevate i3 Device to the end of each Flexco belt cleaner where cutting-edge analytics are immediately aggregated and processed. The information is then wirelessly transferred to the Flexco Elevate Dashboard where operations have immediate, remote access to action-oriented insights and service information for all of the Flexco cleaners throughout the operation.

Flexco Elevate fundamentally alters the way operations are run and the solution’s multi-faceted benefits streamline internal processes. They include:

• Increased Productivity: The Elevate solution makes it easy to manage belt cleaner service.

• ROI from Day One: Data insights are immediately transferred to the dashboard so operations realize operational efficiency from day one.

• Improved Safety: The Flexco Elevate solution reduces the need for dangerous physical inspections along beltlines.

• Asset Management: Digital mapping of installed Flexco cleaners provides visibility of assets for more efficient resource planning.

• No Guesswork: The operations team knows exactly what, when, and where service is needed.

• Leverages Existing Assets: The Elevate Platform works with existing Flexco belt cleaners – no additional investment in cleaners is required.

• Remarkably Easy: Installation and activation in as little as five minutes for a user-friendly experience.

“With the introduction of Elevate, Flexco is reimagining the ways customers can enhance their operations through innovative solutions and added value to belt cleaners and other conveyor components,” said Ryan Grevenstuk, Director of Global Heavy-Duty Marketing.

“Because it has the power to turn complex data into real-world outcomes, Flexco Elevate is able to transform the way operations address pain points – allowing them to make proactive decisions that continually maximize their uptime and productivity.”

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoThe necessity of bolted flange connection training

-

Drive systems6 years ago

Drive systems6 years agoIntelligent frequency inverters for digital production

-

Motors9 years ago

Motors9 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors9 years ago

Motors9 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives8 years ago

Gear drives8 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control8 years ago

Motion control8 years agoWhere the robots come from?

-

Motion control8 years ago

Motion control8 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES5 years ago

POWER TRANSMISSION TECHNOLOGIES5 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoCustom hobbing tool enables 45-degree angles