Chain & Chain Drives

Chains are used frequently in industrial manufacturing environments. Chain systems, which serve efficient solutions in fundamental requirements such as lifting, transporting and drive, find many application spheres in industrial manufacturing. According to usage spheres, chain types can be aggregated in these three topics:

1.Load lifting chains

2.Transfer chains

3.Drive chains

The main criterion in chain choice is the load to be subjected; eg., they should carry an appropriate power transmission potential for the application they will be used.

Load lifting chains, as expressed in the name, are used to carry something from somewhere. Here, the chain shall be used for lifting the material that will be used and, for this reason, pulling force is the main subject at this point. Round steel link chains as the general preference for these tasks, are used often at lifting machines.

Transfer chains, again as expressed in the name, is the general definition for the chain types benefited for transferring materials to elsewhere. For these applications, chains that have rotating skills and round steel link formation are used.

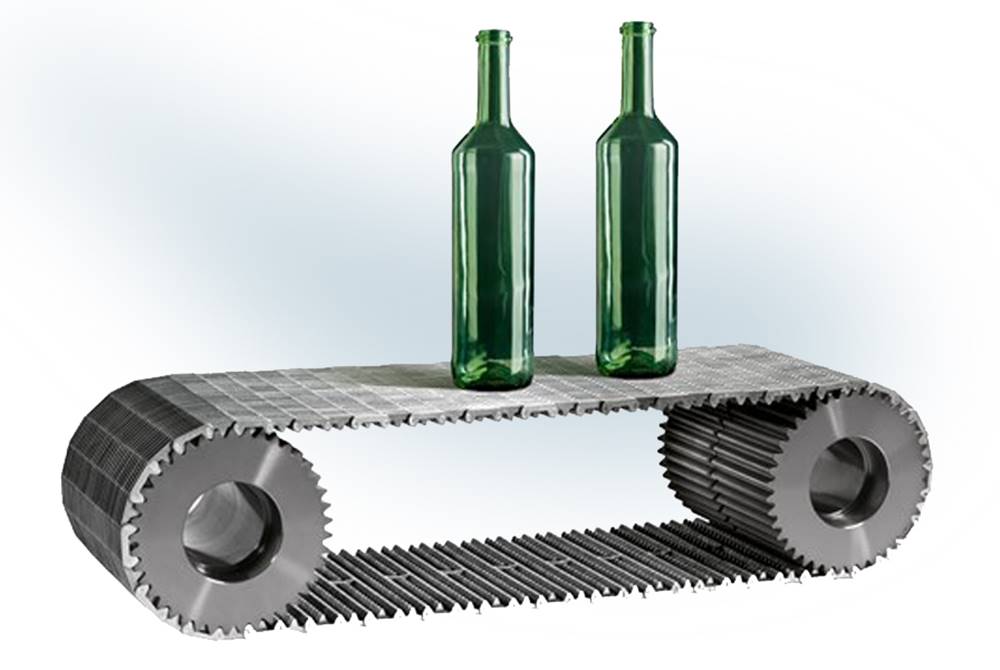

Drive chain is the name given to the chain type which commission to transmit energy emerging at power center to the desired environment. Drive chains are used in many different spheres such as tool centers, food & beverages industry and gearboxes.Despite transfer and drive chains are discrete theoretically, they can be used for the same purposes.

Chain maintenance and proper work

Chains are generally sold as non-packed. These chains’ pitch tips have to be connected, in order to be prepared for usage and this requires expertise.Another critical subject in chains is the tension. For sustainable functioning of chains in compatibility with the gears, without disruption and power loss, they have to be assembled with a pre-tension.

Chains have to be lubricated periodically for preventing subjection to friction caused effects.

It can be told that, compared with belts, chains have quite higher power transmission capability. However, there is a point to be remembered; chain costs are quite much higher than belts.

There are many companies, expert in chain manufacturing and post-sales services in Turkey and in the world.

Chain Types

Heavy Duty Tow chains

A.S.A & B.S. chains

Asphalt conveyor chains

Waste water sanitation chains

Biathlon (insufficient maintenance environment)

Pulling machine conveyor chain

Peripheral conveyor chain

Cement conveyor chain

Outer pulley (collector) chains

Fleer chains

General drive chain

Facility equipment and vibration drives

Welded steel conveyor chain

Bucket elevator chain

Conveyor chain products

Coal mining conveyor chain

Special chains

Stainless chains

Pin nose and drop chains

Pin hole chains

Plastic cap carrier chains

Pulling machine carrier chains

Conveyor series chains

Drive chains

Sheet metal cap carrier chains

Silent chains

Standard attachments

Standard conveyor chain

Drive chain

Conveyor chain for theme parks

Triathlon (high heat non-lubrication)

Trident conveyor chain

Side spring chains

Leaf chains

Escalator chain

High performance chain gears