Motors

Baumüller Develops New DSH Servo Motors for High-Precision Applications

With the new DSH1 series, where “H” stands for high precision, the drive specialist Baumüller has created another derivative in its servo motor range. The latest product by the Nuremberg-based provider of drive and automation solutions impresses with a particularly low detent torque and thus achieves an extremely high control accuracy, especially in combination with the Baumüller drive technology.

Quiet and Extremely Adjustable

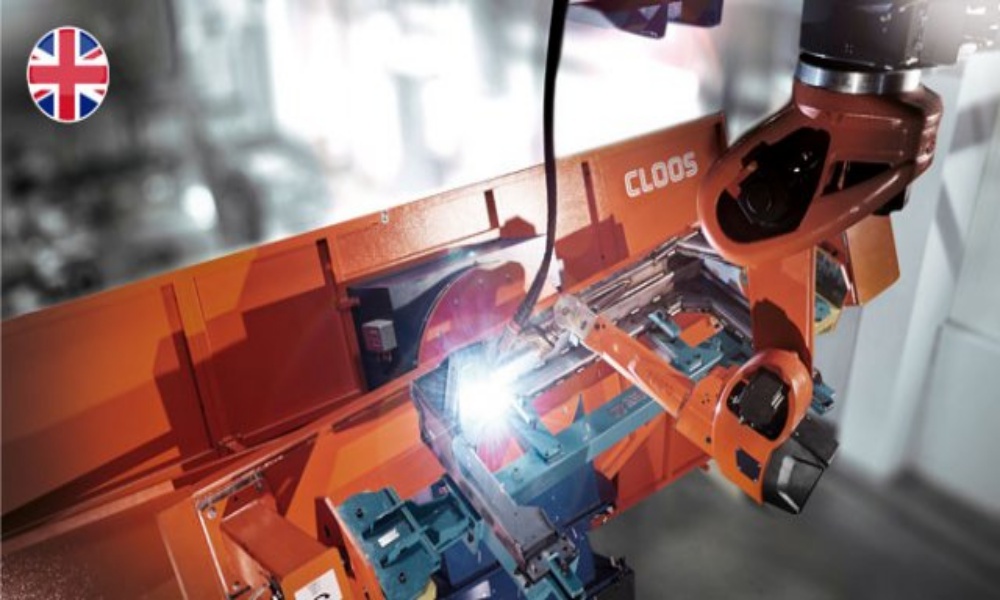

Fotoğraf Açıklama: With their excellent control properties, the servo motors of the new DSH1 series (on the right) achieve the high quality and precision that are required e.g. for specific welding seams

The DSH1 high precision servo motors were developed specifically for applications with the highest standards for quality and smooth operation. Typical areas of application, e.g. in the handling and robot field, include welding robots that produce components with a precise and high-quality welding seam. Due to the excellent control properties of the new servo motors, they are also ideal for label printing machines that have to achieve a consistently high and reproducible print quality.

The new motors can be optimally integrated into the current DS servo motor product range. With the existing modular system, the mechanical interfaces and connection technology are designed analogous to the existing Baumüller servo motors in the DSH1 series as well. This means that depending on the application requirements, the optimal servo motor can be used without requiring the machine manufacturer to make adjustments in the mechanics or connection technology. The maximum rotational speed range of the DSH1 servo motors, which are available in the sizes 45-100, is up to 6000 1/min with rated outputs of up to 10 kW in the self-cooling version.

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoThe necessity of bolted flange connection training

-

Drive systems6 years ago

Drive systems6 years agoIntelligent frequency inverters for digital production

-

Motors9 years ago

Motors9 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors9 years ago

Motors9 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives8 years ago

Gear drives8 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control8 years ago

Motion control8 years agoWhere the robots come from?

-

Motion control8 years ago

Motion control8 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES5 years ago

POWER TRANSMISSION TECHNOLOGIES5 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoCustom hobbing tool enables 45-degree angles