Bearings

New development of the Integrated Gear Bearing “JIGB®”

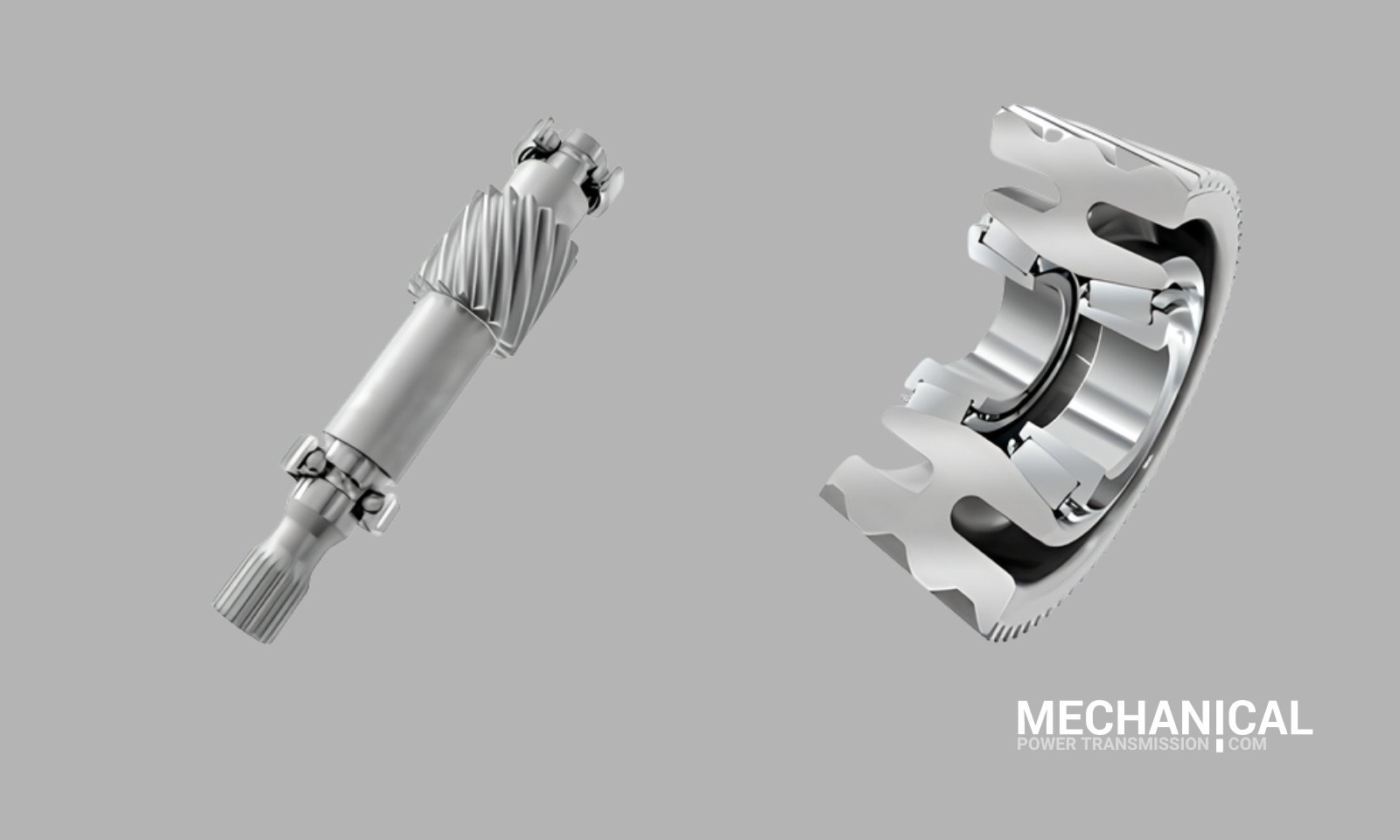

JTEKT Corporation (Headquarters: Kariya City, Aichi Prefecture, President: Yoshito Kondo, hereinafter referred to as “JTEKT”) has developed JIGB® (JTEKT Integrated Gear Bearing®), leveraging the core competencies cultivated in the automotive parts, bearings, and machine tool businesses. JIGB® is the new product that integrates gears and bearings, conventionally assembled as separate components due to different functional requirements in automotive and industrial machinery.

1.Development Background

JTEKT aims to become a solution provider that creates the future of mobility society through manufacturing and manufacturing equipment, under the banner of the JTEKT Group 2030 Vision. The JTEKT Group will promote the utilization of the core competence platform (hereinafter referred to as “CocoPla”), which consolidates competence related to product and manufacturing equipment technologies and knowledge. In addition to the synergy of internal competence, we will establish a solution co-creation center in January 2025 that proposes solutions to internal and social problems by connecting external technologies and knowledge. We will contribute to our customers and society through solution-oriented business.

The mobility industry, including automobiles, is being urged to improve functional value from a wide variety of perspectives. JIGB® is the product that integrated gears and bearings, components of reduction gears in automobiles and industrial machinery, achieves optimal structure for downsizing of the unit, increasing gear strength, and reducing torque loss in bearings. This technology, can be proposed by JTEKT only, utilizes the core competencies developed over many years in gear and bearing products, addressing the challenge of balancing both the toughness required for gear teeth and the durability required for bearings (raceways).

2.Product Overview

Integration of bearings used for the outer diameter of gears

The current gear shafts, which have bearing press-fitted into the shaft, have challenges in reducing torque loss due to size constraints of the bearings and reduction gears, given the shaft diameter. In contrast, the developed product adds a bearing raceway to the outer diameter of gear shaft, integrating it with the bearing. This allows for the omission of the bearing inner ring (raceway), achieving a reduction in bearing outer diameter and unit (distance between shafts) size, as well as a reduction in torque loss. Additionally, omitting the bearing press-in process improves customer productivity.

When assembling bearings inside a gear, rattling during assembly may reduce the overall strength of gears. In contrast, the developed product reduces misaligment of gears by using bearing’s outer ring as gear’s inner diameter, achieving a reduction in gear size and the size of the units. Additionally, eliminating the bearing press-in process for the gear’s inner diameter is also expected to reduce the number of parts.

3.Future Prospects

JIGB® is one of the solutions proposed by JTEKT. As a solution provider creating the future of mobility society, JTEKT develops products that contribute to the performance enhancement of mobility, including automobiles and industrial machinery, and will propose them sequentially.

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoThe necessity of bolted flange connection training

-

Drive systems6 years ago

Drive systems6 years agoIntelligent frequency inverters for digital production

-

Motors9 years ago

Motors9 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors9 years ago

Motors9 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives8 years ago

Gear drives8 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control8 years ago

Motion control8 years agoWhere the robots come from?

-

Motion control8 years ago

Motion control8 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES5 years ago

POWER TRANSMISSION TECHNOLOGIES5 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoCustom hobbing tool enables 45-degree angles