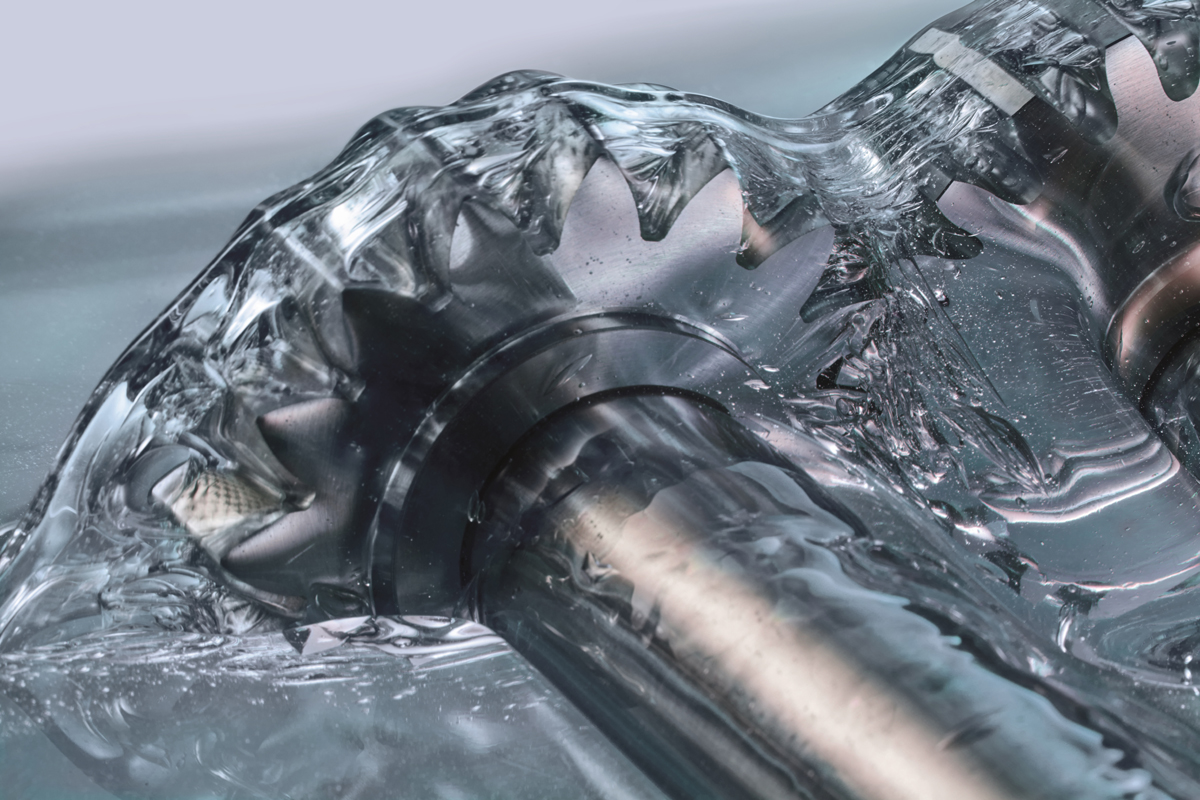

Gears

First Hydro Lubricant for gears

Innovative lubricant containing water as a functional component combines high performance and sustainability.

With the new Hydro Lubricants, Klüber Lubrication succeeded in developing homogeneous lubricants using water as a functional constituent, thus making use of the positive effects of water. This approach offers important benefits both in terms of lubricant performance and sustainability. The high-performance lubricant Klübersustain GW 0-460 for industrial gears is the first product from the innovative Hydro Lubricant series.

“Major advantages of our pioneering lubricant concept are the optimised friction behaviour as well as the excellent cooling characteristics that contribute to lower temperatures in gears and rolling bearings”, explains Matthias Pfadt, Manager Application Engineering at Klüber Lubrication. “The new gear lubricant based on water and a synthetic base oil offers a new performance level which meets the growing requirements and increasing power density of modern gears. It also makes a major contribution to energy efficiency.”

Modern lubricant design for trouble-free operation

Klübersustain GW 0-460 has been developed especially for high-speed spur, bevel and planetary gears, as its low foaming tendency ensures uninterrupted operation of components. The excellent viscosity-temperature behaviour supports the formation of a sufficient lubricant film across the whole service temperature range. Its good electric conductivity also protects components against electro-corrosion.

The Hydro Lubricants from Klüber Lubrication are based on a modern lubricant design that has the potential to revolutionise the future of speciality lubricants and solve future challenges with regard to performance, energy efficiency and environmental compatibility of lubricants. Together with cooperation partners from different sectors, Klüber Lubrication is currently working on Hydro Lubricants for various applications and components.

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoThe necessity of bolted flange connection training

-

Drive systems6 years ago

Drive systems6 years agoIntelligent frequency inverters for digital production

-

Motors9 years ago

Motors9 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors9 years ago

Motors9 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives8 years ago

Gear drives8 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control8 years ago

Motion control8 years agoWhere the robots come from?

-

Motion control8 years ago

Motion control8 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES5 years ago

POWER TRANSMISSION TECHNOLOGIES5 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoCustom hobbing tool enables 45-degree angles