Robotics Technologies

Cobots enable effective high-mix, low-volume production

With increased competition, often on a global scale, manufacturers need to differentiate themselves by tailoring products more closely to customer demand. This, of course, carries with it an implicit reduction in batch sizes and has seen the rise of ‘high-mix, low-volume production. Cobots can enable manufacturers to effectively meet individual customer requirements with greater product variety in smaller batches. Oliver Giertz, Product Manager for Servo/Motion and robotics for the EMEA region at Mitsubishi Electric, Factory Automation, explains how collaborative robots are helping manufacturers to increase flexibility, boost quality, and drive down operational costs.

While high-volume production, with its repetitive tasks, has seen increased adoption of traditional industrial robots, we have to think differently in a high-mix production environment where the programming and reconfiguration effort to change from one product to the next can impact on productivity. In high-mix production, there might be several line changeovers needed in a given shift.

For many manufacturers, this has meant an increased reliance on manual labour. But that, in turn, increases operational costs when compared with high-volume production – and the greater the mix, the higher the emphasis on manual labour, and the greater the production cost for a given volume.

Further, high-mix, low volume (HMLV) production requires more stringent quality control processes to be put in place, with the opportunity for production errors increasing as the batch sizes reduces. At the same time, the levels of changeovers between different products can often become a bottleneck.

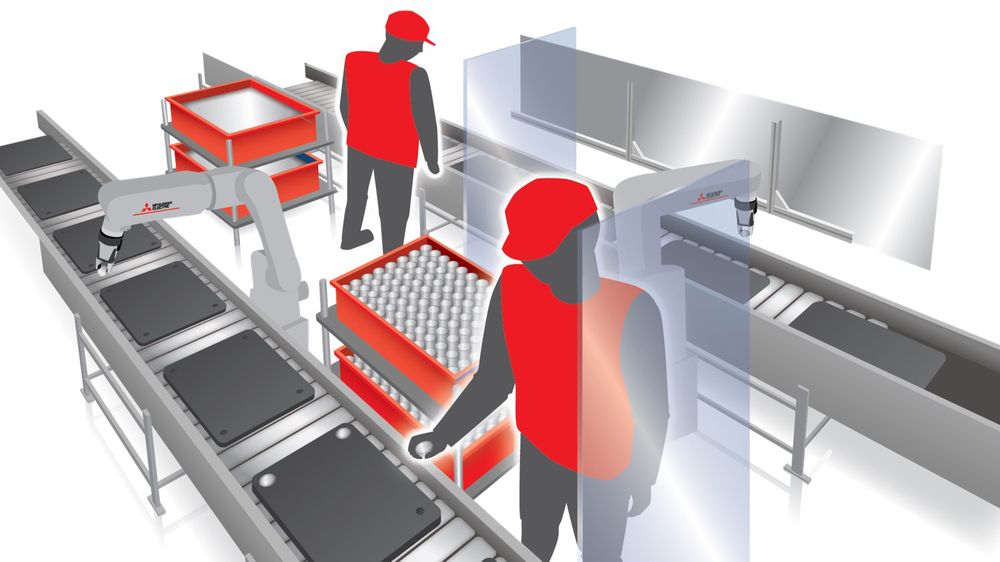

However, the new breed of collaborative robots (or cobots) is responding to the trend of HMLV production, delivering the required flexibility and the ability to reconfigure processes quickly as well as easily.

Improved flexibility, consistency and reliability

Designed to assist human operators on the shop floor, cobots can take on simple, repetitive and physically strenuous tasks. This offers improved consistency and reliability in manufacturing while enabling humans to concentrate on more complex jobs. A cobot is also flexible and can quickly learn to adapt to a variety of tasks, from picking and placing to machine tending.

A key benefit of cobots is their ease of programming, enabling frequent redeployment and fast set-up without advanced robotic programming expertise. One recent development which can improve the ease and speed of configuration is hand-guided teaching, where the cobot arm is simply moved to the desired position and added to the operational sequence at the press of a button. This technology means that no complex programming is required, and it can also be combined with touch-screen graphical interfaces to implement more sophisticated operations.

A digital twin can also be used to enhance the speed of set-up and redeployment. Employing a digital representation of the physical cobot, including the virtual capability to evaluate performance, the digital twin can simulate cobot interaction to ensure that it can safely and predictably fulfil the desired task before deployment.

This ease of programming and redeployment is one of the main enablers of HMLV production and holds the key to reducing operational costs. At the same time, the increased accuracy of the latest cobots is an important contributor to improving quality in a high-mix environment. As an example, Mitsubishi Electric’s MELFA ASSISTA cobots can provide a repeat accuracy of ±0.03mm, making them ideal even for the most delicate and precise tasks.

By moving towards HMLV production, manufacturers are finding that they can differentiate themselves from their competitors, with the ability to tailor products to specific customer requirements, even in the smallest of batches. Further, with the ability to quickly switch production to a different product, manufacturers can become more responsive to changes in the market, delivering an additional competitive advantage.

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoThe necessity of bolted flange connection training

-

Drive systems6 years ago

Drive systems6 years agoIntelligent frequency inverters for digital production

-

Motors9 years ago

Motors9 years agoNew generation of hollow shaft motors

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoABB and Formula E partner to write the future of e-mobility

-

Industrial Hardware and Machine Parts8 years ago

Industrial Hardware and Machine Parts8 years agoRexnord adds to its Autogard Torque Limiters with the XG Series

-

Motors9 years ago

Motors9 years agoZF Technology on the Winners’ Podium of the Dakar Rally 2017

-

Gear drives8 years ago

Gear drives8 years agoKlingelnberg at control 2018: Tactile and optical measurement on one machine

-

Motors8 years ago

Motors8 years agoGet a first-class ticket to productivity

-

Motion control8 years ago

Motion control8 years agoWhere the robots come from?

-

Motion control8 years ago

Motion control8 years agoRexnord to Acquire Centa Power Transmission

-

POWER TRANSMISSION TECHNOLOGIES5 years ago

POWER TRANSMISSION TECHNOLOGIES5 years agoEUROTRANS Board meets for its first session in 2021

-

Industrial Hardware and Machine Parts9 years ago

Industrial Hardware and Machine Parts9 years agoCustom hobbing tool enables 45-degree angles